Feasibility report of hollow plastic building formwork equipment

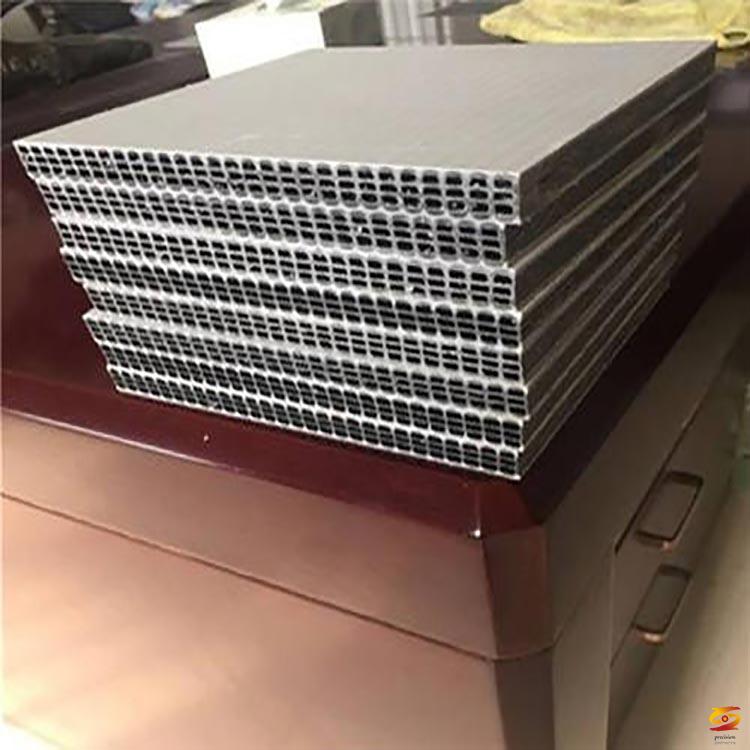

Feasibility report of hollow plastic building formwork equipmentThe PP plastic hollow building template production line can range from 8-18mm in sheet thickness, and the sheet width can be customized to 915-1220mm according to customer requirements. Its products have smooth surface, small dimensional error, and have many advantages such as nailability, planing, corrosion resistance, and strong flame retardancy.

The PP plastic hollow building template production line consists of a single-screw extruder or twin-screw extruder, hydraulic screen changer, metering pump mold, sizing plate, primary tractor, cooling bracket, secondary tractor, cross-cutting machine, automatic drop Plate manipulator composition.

1. Features and advantages of hollow plastic building formwork

lower the cost. Turnover of hollow building formwork has reached more than 50 times

Energy saving and environmental protection. The hollow building template has no harmful gas release, and the template can be repeatedly processed and regenerated after it is scrapped.

Smooth and neat. The surface of the hollow building template is smooth and flat, and the demoulding effect exceeds the technical requirements of the clear water template, eliminating the need for secondary plastering.

Stable and weatherable. The hollow building template is anti-aging, acid and alkali resistant, corrosion resistant, and has a small expansion coefficient.

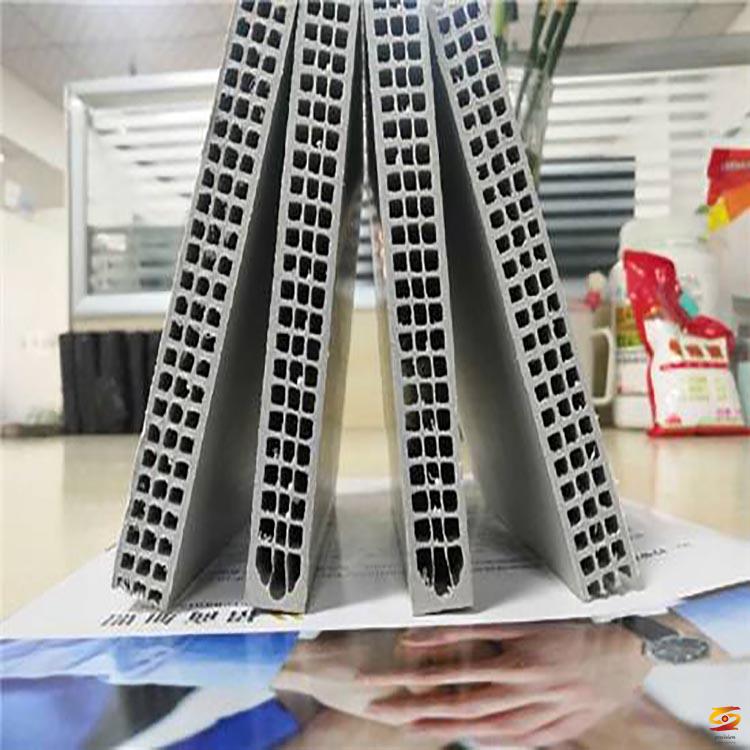

Superior performance. The hollow building template has high strength, good toughness, no cracking, no delamination.

Lightweight and easy to install. Light weight and easy to install, each weighs 14-15KG, which is only one-half of the wooden template, saving time and effort for workers.

Recycling at a high price. After the template is scrapped, the company can recycle it at a high price.

Convenient storage. The hollow building template is cold-resistant, high-temperature resistant, and insect-proof, and no special treatment is required for storage.

Easy demoulding. The mold release does not need to brush the mold release agent, and it is easy to release the mold.

Strong variability. The template can be cut, cut, and drilled arbitrarily.

two. Parameters of hollow plastic building formwork

1. Dimensions: width: 915mm, length: 1830mm, thickness: 14mm, 15mm, 16mm.

2. Weight: 14mm thick, a board weight 13.5±0.5kg

The thickness of 15mm, the weight of a board is 14±0.5kg

The thickness of 16mm, the weight of a board is 15±0.5kg

3. Comparison of the use of hollow composite plastic and formwork wood formwork (bamboo wood formwork)

name

Hollow composite plastic template

Wood template (bamboo and wood template)

unit price

100 yuan/㎡

Above ground: 30 yuan/㎡

Underground: 20 yuan/㎡

weight

light

weight

usage count

50-100 times

5-8 times

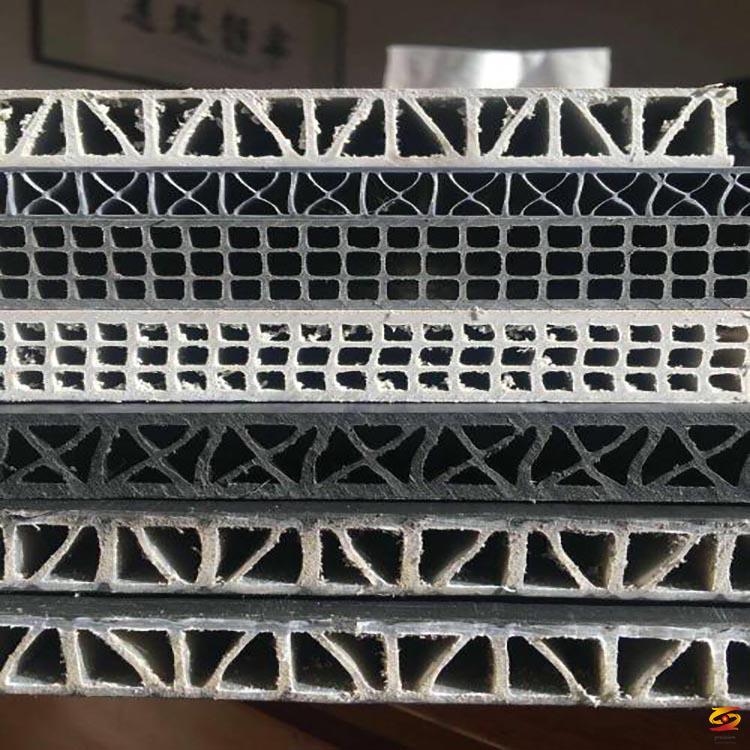

four. Comparison table of cost performance of various templates

Template type/performance

Hollow plastic template

Ordinary plastic template

Bamboo and wood template

Aluminum alloy template

Abrasion resistance

Wear-resistant

Wear-resistant

Not wearable

Wear-resistant

Corrosion resistance

preservative

preservative

Not resistant to corrosion

preservative

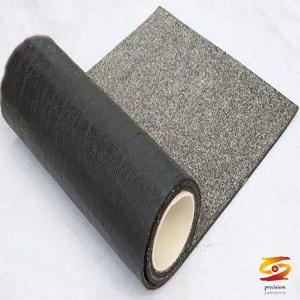

toughness

Can be bent into arch formwork

Can't

Can't

can

Impact strength

high strength

general

difference

general

After absorbing water

Not deformed

Not deformed

Easy to break and deform

Not deformed

Customized size

customizable

customizable

Not customizable

customizable

Releasability

Self demoulding

Self demoulding

Brush release agent

Brush release agent

Warpage after use

No warpage

Easy to warp

Easy to warp

No warpage

Weight (kg/m²)

8kg

15kg

7.2kg

25kg

Recyclability

Recyclable

Recyclable

Not recyclable

Recyclable

Processability

Easy to process

Easier

difficult

difficult

Environmental protection

No pollution

No pollution

polluted environment

No pollution

The cost

low

high

high

high

Turnover

50-100

20-30

3-6

80-100

Price (yuan/m²)

80 yuan

75 yuan

35 yuan

800 yuan

Residual value (yuan/m²)

25 yuan

18 yuan

1 Yuan

200 yuan

Share price (yuan/m²)

1.1 yuan

2.8 yuan

5.6 yuan

6 yuan

V. Comparison of the use cost of hollow plastic construction formwork and wood formwork (bamboo and wood formwork) in 3 buildings

Hollow composite plastic template

Wood template (bamboo and wood template)

Cost of the first building:

7500㎡x100yuan/㎡=750000yuan

Above ground: 7500㎡x30yuan/㎡=225000yuan.

Above ground: At least 3 batches of templates are required for a 30-story building, and the above ground cost is: 225000x3=675000 yuan

Underground: 1000㎡x3x20 yuan/㎡=60,000 yuan.

Total: 675000+60000=735000 yuan.

Cost of the second building:

1. The apartment type is the same, the utilization rate is 100%, and the cost is: 0;

2. Take the different types of houses as an example: the utilization rate is 70%, and the cost is: 7500㎡x30%x25=56250 yuan (the old trade-in price is 25 yuan/㎡)

Same cost as the first building template, 735,000 yuan

Cost of the third building:

Same as the cost of the second building.

The same cost 735,000 yuan

Total cost of 3 buildings

750000+56250+56250=862500 yuan

Recycling: 7500㎡x30 yuan/㎡=225000 yuan (recycling: 50 yuan/sheet)

The actual use cost is: 862500-225000=637500 yuan.

735000×3=220500 yuan.

six. Production equipment for hollow plastic building template

PP hollow building formwork equipment 2PP hollow building formwork equipment

Main equipment configuration

One

SJ-120 single screw extruder

set

two

SJ-65 single screw extruder

set

three

Hydraulic quick screen changer

Two sets

four

Metering pumps

Two sets

Fives

Distributor

set

six

Hollow sheet mould

set

Seven

Cooling and shaping platform

set

Eight

Cooling bracket and trimming device

set

nine

Traction device

set

ten

Cutting Machine

set

eleven

Stacking rack

set

twelve

30P chiller

set

thirteen

Vertical Dry Mixer

set

fourteen

Electrical control system

It can be seen from the comparison that the use of hollow composite plastic formwork is about 35% of the cost of bamboo and wood formwork, which has good economic value and saves construction costs.

If you want to know more about it please do not hesitate to

contact me. WhatsApp:+86-15966835076.