PVC pipe production problems and solutions

PVC pipe production problems and solutionsThere are always various problems in the process of PVC pipe production. Only by solving these problems can high-quality PVC pipes be produced. To share with you some PVC pipe production problems and solutions.

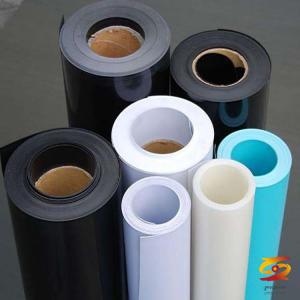

pvc tube

1. The outer surface of the plastic pipe is rough: adjust the process temperature: reduce the cooling water temperature, the optimal cooling water temperature of the PE pipe is 20 ~ 25 ℃; check the waterway for blockage or insufficient water pressure; check whether the heating ring of the barrel, machine head, etc. There is damage; adjust the inlet water flow of the sizing sleeve; consult the raw material supplier, the raw material parameters of this batch; check the mold core temperature, if it is higher than the temperature of the die section, lower the core temperature; clean the mold;

2. Groove marks appear on the outer surface of the plastic pipe: adjust the outlet pressure of the sizing sleeve, and the water output requirement is balanced; adjust the nozzle angle in the vacuum sizing box to make the pipe cool evenly; check the hardware such as die, sizing sleeve, cutting machine, etc. Objects, burrs, etc .;

3. Groove marks appear on the inner surface: check whether the inner tube is filled with water. If the water enters, pinch the tube blank of the outlet mold tightly to make the inner cavity closed; reduce the internal temperature of the mold; clean and polish the mold;

4. There is a jitter ring inside the pipe: adjust the outlet of the sizing sleeve to make the water even; adjust the vacuum degree of the second chamber to make the vacuum degree of the rear chamber slightly higher than the vacuum degree of the front chamber; check whether the vacuum seal is too tight; check the pvc pipe production line Whether there is jitter in the traction machine; check whether the main machine discharges evenly;

5. No vacuum: check whether the water inlet of the vacuum pump is blocked, if it is blocked, use a needle to dredge; check whether the vacuum pump works normally; check whether the vacuum pipeline is leaking; check whether the small hole in the middle of the mandrel compression screw is blocked, such as blocking Dredge with thin iron wire;

6. Outer tolerance of the outer diameter of the pipe: adjust the size of the vacuum degree to change the size of the outer circle; adjust the traction speed to change the size of the outer circle; modify the size of the inner hole of the sizing sleeve;

7. Out-of-standard pipe quality: adjust the nozzle angle in the vacuum setting machine and spray box to make the pipe cool evenly; check the water level height and water pressure gauge pressure in the vacuum setting machine and spray box to make the spray volume large and powerful; Check the water temperature of the vacuum setting machine and spray box. If it is> 35 ℃, you need to configure a chilled water system or add a spray cooling box; check the waterway and clean the filter; adjust the process; check and correct the hole size of the sizing sleeve; adjust Pipe guiding clamping device to correct the ellipticity of the pipe;

If you want to know more about it please do not hesitate to

contact me. WhatsApp:+86-15966835076.