PVC wood plastic crust foam building template Project feasibility proposal

PVC wood plastic crust foam building template Project feasibility proposalFeasibility report of PVC foam board as building template

table of Contents

Preface

1. Introduction and market prospects of wood-plastic building formwork projects

2. Production process and flow chart of wood-plastic building template

3. Whole plant production equipment for wood-plastic building template

4. User-supplied projects and equipment installation and commissioning

5. Feasibility analysis of PVC wood-plastic building template project

Six, PVC wood plastic building template equipment supporting plan

7. Quality and Service Commitment

Preface

Our company is located in the beautiful coastal city of Jiaozhou City, Qingdao. It is a modern technology enterprise integrating science, industry and trade. The main products are SPC stone plastic floor equipment, various hollow product processing equipment, and plastic pipe sheet sheet profile extrusion production lines. All kinds of plastic machinery, molds and plastic products, the products are spread all over the country and more than 50 countries and regions in the world. For many years, the company has always followed the idea of customer first and quality first, providing users with high-quality plastic machinery and equipment and a full range of services, and enjoys a high reputation in the same industry at home and abroad.

Our company has developed wood-plastic machinery and equipment with international advanced level. The wood-plastic products produced make full use of abundant wood side materials, crop straws, plastic waste, etc. to realize "wood-plastic replacement" and protect limited forest resources. , Reducing "white pollution", is a national key promotion project. Used by users at home and abroad, it has won high praise and trust from customers.

1. Introduction and market prospects of PVC wood-plastic building template project

(1) Product background

Building template is an important tool for concrete structure engineering construction. In cast-in-place concrete structure engineering, formwork engineering generally accounts for 20%-30% of the concrete structure engineering cost, 30%-40% of the engineering labor cost, and about 50% of the construction period. Formwork technology directly affects the quality, cost and benefit of project construction, so it is an important content to promote the progress of my country's construction technology.

At present, the main formwork for construction in my country is wood formwork. According to the statistics in 2009, the market size of wood plywood formwork was 300 million square meters, its annual output was 77.3 million square meters, and the market size of bamboo plywood formwork was 122 million square meters. The annual output is 31.4 million square meters. At present, China's total timber demand is more than 100 million cubic meters, while the market supply is only more than 60 million cubic meters, with a gap of about 40 million cubic meters. The formwork alone requires more than 3 million cubic meters of wood. my country's timber resources are scarce, and importing timber will cost a lot of foreign exchange. At present, there are two ways to solve this problem: on the one hand, it is to encourage the import of wood; on the other hand, it is to seek wood substitutes through the research and development of new materials. Wood-plastic template has become the preferred substitute. Many foreign countries such as the United States and Canada have invested heavily in the development of wood-plastic projects.

The production scale of my country's construction formwork industry will maintain a growth rate of about 10% in 2010; the average annual growth rate of production scale of my country's construction formwork industry will be around 15% from 2011 to 2012; by the end of 2012, the output of my country's construction formwork industry will reach 220 million About square meters. The average annual total demand for construction formwork panels is conservatively calculated to be more than 200 billion yuan, and it is increasing at an average annual rate of 9-12%. In the next 2-3 years, wood-plastic building templates will occupy 30%-50% of the market share, and the output value will reach about 60-100 billion. The market prospect is very broad.

(2) Performance comparison of common building templates

1. The wooden formwork was the first to be used. Because a large amount of wood is consumed, and the disassembly formwork is easy to split, the loss rate is relatively high, and the general turnover is 4-6 times. For our country where forest resources are not abundant, we should seek alternative products.

2. Steel formwork: The advantage is that it can save a lot of wood, but it also has many unsatisfactory points:

(1) The cost is high, the average price is 280 yuan/square meter, which is much higher than the price of wood-plastic template;

(2) Bulky, inconvenient construction and lifting, and difficult to disassemble. The area of a single template is not large, and there are many splicing blocks in use, which is time-consuming and laborious;

(3) The steel formwork has a strong affinity with cement. When the formwork is removed, it is easy to peel off the surface of cement products such as columns or beams, which affects the quality;

(4) The steel template is easy to rust.

3. Advantages of PVC wood plastic building template:

①Can save a lot of wood;

②It has advantages in convenience and safety of construction;

③WPC does not require maintenance and can be recycled, so production costs can be greatly reduced, and many key problems in engineering can be solved.

(Three) PVC wood plastic template performance and advantages

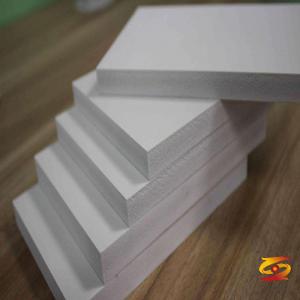

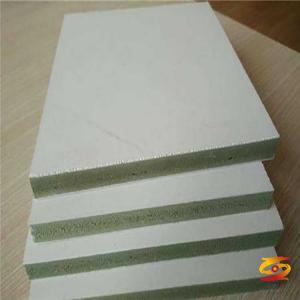

Wood plastic formwork processing WPC formwork application

PVC wood-plastic template is a new type of environmental protection material compounded by plant fiber and PVC resin.

The annual output of plastic products in my country exceeds 40 million tons. Ranked second in the world, about 13.84 million tons of waste plastics are produced every year. The output of domestic agricultural plant fiber is tens of millions of tons, wood materials are more than 1 million tons, and other natural fibers are also 5-10 million tons, which provides a rich raw material foundation for the development of my country's PVC wood-plastic template.

1. Features of PVC wood-plastic composite materials:

(1) There are wide sources of materials and low value.

(2) Wood-plastic products are artificial overall synthetic products, and the product process and formula can be adjusted randomly according to the requirements of use, so as to produce materials with different properties and shapes, and the utilization rate of its profile is close to 100%.

(3) The wood/plastic base material of PVC wood plastic material and its commonly used additives are environmentally safe, non-toxic and harmless, and there will be no side effects during the production and processing process, so it does not pose any harm to the human body and the environment.

(4) The maintenance cost is extremely low, and the product life span is several times that of ordinary natural wood,

(5) Scrap products and recycled waste products of PVC wood plastic materials can be 100% recycled, and will not affect product performance.

2. Advantages of PVC wood plastic building template

(1) There are wide sources of raw materials, low overall cost, and certain competitiveness in the market;

(2) The basic performance is equivalent to that of wood, which can be sawn, nailed, and corrosion-resistant, and its products have better durability than wooden and bamboo building templates;

(3) The product assembly is flexible and can be changed according to the specific requirements of the market and users;

(4) High reuse rate and recyclable;

(5) Not afraid of insect bites, acid and alkali resistance, aging resistance, not easy to absorb water, and easy to peel off from concrete.

(4) Performance and price comparison between PVC wood plastic building template and mainstream template:

Performance item

Wood material

Steel material

All plastic material

Plastic wood composite

proportion:

G/cubic centimeter

0.8-1.1

7-8

0.9-1.1

0.6-0.7

Rigidity and load capacity

Higher

high

low

Higher than wood and

All plastic material

Machinability

easy

Not easy

not easy

easy

Durability

limited

(Easy to corrosion)

limited

(Easy to corrosion)

Higher

High (7-10 times

Wood material)

Water absorption

high

Does not absorb water

Does not absorb water

Does not absorb water

Solar aging resistance

it is good

it is good

difference

it is good

Acid and alkali resistance

difference

difference

excellent

excellent

Resistance to environmental pollution

Poor

better

it is good

it is good

Maintenance frequency

And difficulty

high

Convenience

Lower

Difficult to repair

Lower

Not repairable

low

Convenience

Recyclability

difference

difference

Recyclable but performance

Lower

100% renewable

Disposal of waste materials

Abandoned or

Payment recovery

Harder,

Payment recovery

Lower price entry

Waste plastic market

Can be traded in

Use safety

(Spiked wood thorns, etc.)

difference

Poor

it is good

it is good

Structural size flexibility

high

low

low

highest

Handling with existing logistics

Equipment adaptability

high

Difficult

Difficult

high

Automated logistics handling

Equipment adaptability

difficult

it is good

difficult

it is good

2. Production process and flow chart of wood-plastic building template

(1) Production process route

Wood flour+PVC resin+auxiliary---extrusion--sizing--cutting--packing

(2) Production process flow chart

raw material

↓

→ mix

↓

Put into the hopper ↓

Melt plasticization

↓

Extrusion through the die

↓

Shape cooling

↓

Traction

↓

Cut to length

↓

Shattering and recycling of defective products ← Qualified products are put into storage

(3) Production process description

First, put PVC, wood flour, filler and other functional additives into the high-speed mixer, mix evenly and put them into the hopper of the extruder through the screw automatic feeder. At the same time, the temperature of the extruder is preset and kept warm. Exit the machine to melt and plasticize the raw materials. Ruijie people extrude into the shaping device through a special die to cool and shape, and pull it out by traction, enter the automatic cutting machine to automatically cut to the stacking rack according to the preset length, and store qualified products, defective products and leftovers Reuse after crushing and grinding.

(4) Main raw materials

1. PVC

2. Wood flour

3. Filler

4. Functional additives

3. Whole plant production equipment for wood-plastic building template

(1) Equipment composition

1. SRL-500/1000 plastic heating and cooling mixing unit

2. SJFB-Z80X22 PVC wood plastic crust foaming building formwork unit

3. SWP-500 plastic crusher

4. SMP-400 high-speed vortex mill

(2) Detailed technical parameters

1. SRL-500/1000 plastic hot-cold mixing unit, feeder

The plastic hot-cold mixing unit is mainly used for the mixing, drying and coloring of raw materials. The pot body is welded by stainless steel. There are heating jackets and electric heaters on the surface of the pot.

Model SRL-500/1000

Total volume of hot mixing 500L

Effective volume 370L

Each feeding amount 150-200kg/pot

Mixing time 6-15 minutes

Hot mixing paddle speed 860r/min

Thermal mixing motor power 55/67KW two-speed motor

Heating method Electric heating, self-friction

Temperature control method Digital display intelligent temperature control instrument

Total volume of cold mix 1000L

Effective volume of cold mix 650L

Cold mixing motor power 11KW

Rotating speed of cold mixing slurry ≤60r/min

Blade material Stainless steel integral casting structure

Lid opening control Pneumatic control

Discharging method Pneumatic valve discharge

2. SJFB-Z80X22 PVC wood plastic crust foaming building formwork unit

a. Automatic feeding machine

b.SJ-Z80X22 special conical twin screw extruder for wood plastic

SJ-Z80 wood-plastic conical twin-screw extruder is an efficient wood-plastic extrusion equipment developed by Qingdao Ruijie. Segmented fault alarm for easy detection. The high-performance deceleration torque distribution system ensures the reliable operation of the equipment. The optimized design and carefully made screw barrel has excellent plasticizing effect. The host is equipped with a PID intelligent temperature control system and automatic temperature control. Equipped with vacuum exhaust, forced feeding mechanism and other devices.

Screw material 38CrMoAl high-quality alloy steel is nitrided twice, and the front end is treated with bimetal

Screw diameter Φ80/156mm

Effective length 1800mm

Quantity 2

Speed 1-36.9 r/min

Nitriding depth 0.5-0.7mm

Barrel material 38CrMoAl high-quality alloy steel is nitrided, and the inner wall is drawn groove sprayed with bimetallic treatment

Heating method: cast aluminum electric heating

Heating zone 5 zone

Heating power about 28KW

Temperature control method Imported brand temperature control instrument, PID intelligent automatic control

Cooling method Fan cooling

Cooling power 4×0.55KW

Host drive power 75KW

Motor speed regulation method

Gear box form Gear material adopts 20CrMoTi grinding and nitriding treatment

Distribution box form Gear material adopts 38CrMoAlA gear grinding and nitriding treatment

The connecting shaft is made of 40Cr, and the bearing is imported

Feeding method: screw automatic quantitative feeding

Screw speed 0-34r/min

Motor power 1.5KW

Speed regulation mode Inverter speed regulation

Vacuum pump form Water ring vacuum pump

Motor power 4KW

Vacuum degree -0.06Mpa

c. Extrusion die

Form Clothes hanger mould

Die material is made of high-quality stainless steel forgings and the inner runner surface is polished

Mold cavity Polished to a bright mirror surface

Die lip with adjustable bolt

Heating method adopts stainless steel electric heating rod to heat

Mold width 1320mm

Product width 1220mm

Product thickness 3~20mm

Temperature measuring element Thermocouple

Mould trolley, bracket type, with walking wheels

d. Foam board forming machine

Vacuum shaping cooling mold size: 1500mm×600mm

Number of vacuum shaping cooling molds: 4 groups (8 pieces)

Upper shaping cooling mold lifting method: pneumatic

Cooling method: water cooling

Shape thickness adjustment: 3-20mm adjustable

Front and rear walking unit Worm gear drives rack and pinion

e. Roller supporting cooling device

Roller diameter X effective length: 80X1400mm

Number of rollers: 20

Vertical arrangement length: 5000mm

f. Edge trimming device

Cutting method: electric saw blade type and blade type two structures.

Sawing motor power: 1.1KWX2 sets

Trimming width: adjustable

Vacuum cleaner motor power: 1.5KW

g. Tractor

Traction roller diameter X effective length: 220X1400mm

Number of traction rollers: 16

Hauling speed: 0-2m/min

Drive motor power: 11Kw

Speed regulation method: frequency conversion speed regulation

Maximum traction: 100KN

h. Cutting machine

Maximum cutting width: 1400mm

Maximum cutting thickness: 20mm

Cutting motor work

Rate: 3Kw

Action: Linkage with length counting device, automatic cutting according to set length, automatic control.

Vacuum cleaner motor power: 1.5KW

i. Material accumulation platform

Vertical length: 3000mm

3. SWP-500 plastic crusher

Number of rotating knives: 9 pieces

Number of fixed knives: 2 pieces

Rotary knife fixed knife material: 9SiCr

Sieve plate aperture: 5-12mm

Feeding port size: 530mmx400mm

Broken size: 3-12mm

Output: 150-300Kg/h

Drive motor power: 15Kw

4. SMP-650 high-speed vortex mill

Grinding chamber diameter: 390mm

Spindle speed: 3000r/min

Drive motor power: 55Kw

Output: 400-600Kg/h

4. User-supplied projects and equipment installation and commissioning

(1) User-provided items

1. Public facilities

A. Power facilities

Power 380V×50HZ ×3 phase

Total installed capacity 250KW

B. Air source

Air pressure 0.7Mpa 0.5-1.0m3/min

C. Water source

Circulating water 10m3/h 15℃

2. Civil works such as plant and equipment foundation

3. Installation tools, including lifting tools, spirit level, etc.

(2) Installation and commissioning

1. The unit should be placed in a good place with a ground concrete foundation greater than 30cm.

2. The extruder can be fixed with M16 metal expansion bolts, and the rest are laid flat on the ground and not fixed.

3. Place each part of the equipment according to the layout drawing of the production line and calibrate the centerline and level of the unit. The distance between auxiliary machines can be adjusted appropriately according to the workshop site conditions. Auxiliary equipment such as electric control box and mixer shall be placed in a convenient place for operation and maintenance according to actual conditions.

4. The electrical appliances of the unit must have good grounding protection.

5. After the installation is completed, connect the electricity, water and gas pipelines.

6. Check whether the parts are loose or falling off.

7. Check whether the rotation of each transmission component is normal.

8. Debug each part of the equipment separately, and then enter the whole machine debugging after the operation is normal.

5. Feasibility analysis of PVC wood-plastic building template project

(1) Basic composition of raw material formula and raw material cost analysis:

1. Analysis of basic composition of raw material formula:

Name Percentage Reference Price

PVC resin powder 10% 6300 yuan/ton

Wood flour 5% 700 yuan/ton

CaCO3 25% 900 yuan/ton

Functional additives 10% 15,000 yuan/ton

Recycled material 50% 3500 yuan/ton

Total raw material cost: 4140 yuan/ton

2. Analysis of processing cost: electricity fee + labor + water consumption + other = about 600 yuan/ton

3. Total cost: 4140 yuan/ton+600 yuan/ton=4740 yuan/ton=4.74 yuan/kg

4. The cost of a single board (take 1830×915×15mm board as an example, weight 16.5 kg): 4.74 yuan/Kg×16.5Kg/piece=78.21 yuan/piece

(2) According to the profitability analysis of a production line, the number of employees and the tax paid to the state:

1. Output value: calculated at 500 sheets/day

Annual output: calculated on the basis of 300 days of annual production, an annual output of 150,000 sheets

Annual production value: 150000×120 yuan/sheet = 18000000 yuan (calculated based on the current market price of 120 yuan/sheet)

2. Annual profit: 150,000 sheets × (120 yuan / sheet-78.21 yuan / sheet) = 6,268,500 yuan

3. Number of labors: 4 workers are employed per shift, and production is divided into 2 shifts every day, totaling 8 workers

(3) According to the normal business scale of the company, five production lines are needed to meet the market demand of a county. If the sales channels radiate to surrounding counties and cities, the business scale of the company will need to be expanded accordingly. Calculated according to the company's operating scale of 5 production lines:

1. Annual production value: 18 million yuan × 5 production lines = 90 million yuan

2. Annual profit: 6,268,500 yuan × 5 production lines = 3,1342,500 yuan

3. Number of employees: a total of 52 jobs can be provided for the society

Production workers: 8 people × 5 production lines = 40 people

Sales staff: 5

Logistics management staff: 6

Technical staff: 1

Six, PVC wood plastic building template equipment supporting plan

Serial number

Equipment name

unit

Quantity

unit price

(Ten thousand yuan)

use

1

SRL-500/1000 Plastic Heating and Cooling Mixing Unit

station

1

Plastic wood powder mixing, drying, coloring, etc.

2

SJFB-Z80X156 PVC wood plastic crust foaming building formwork unit

station

1

Production width 1220mm wood plastic board

3

SWP-500 plastic crusher

SMP-650 High Speed Eddy Current Mill

station

Each 1

Crushing and recycling scraps

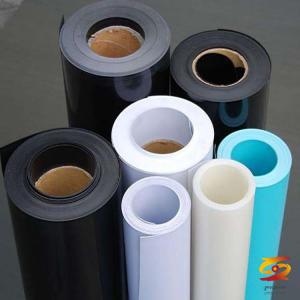

PVC wood-plastic foam board production line equipment can also produce current net mahogany wood veneers, furniture boards and advertising lettering boards.

If you want to know more about it please do not hesitate to

contact me. WhatsApp:+86-15966835076.