Description

Equipment introduction:

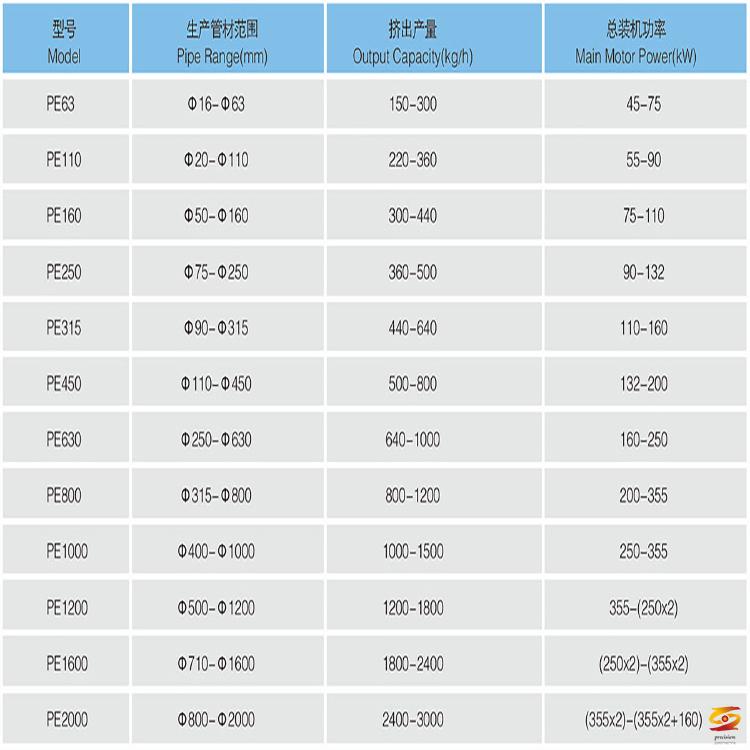

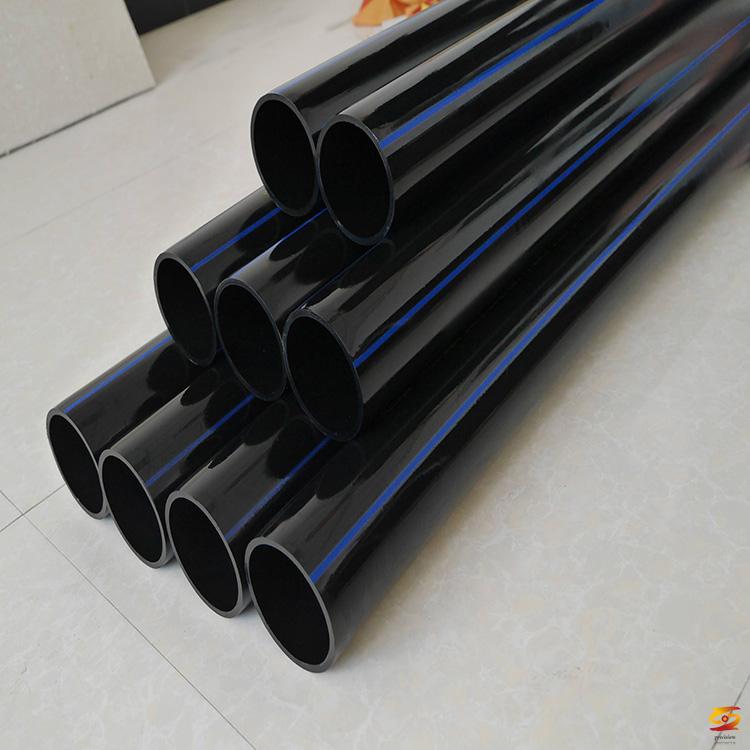

Our PE pipe extrusion line can produce PE pipe size range from Ø16 to Ø2000mm.

PE pipes can be used for threading pipes, water supply, gas supply, drainage, liquid transportation, electrical conduits, etc.

Our PE pipe extruder can process different kinds of PO materials: PP, PPR, PERT, PB, PEX-B, etc.

We can provide different PE pipe extrusion lines: normal or high speed, single or multi-layer, single or double output (double output and four output are suitable for small pipe diameter).

Technical features:

Using advanced European technology and based on years of experience in plastic machinery research and development and production, our company has developed a high-efficiency and energy-saving PE pipe extrusion production line with advanced design, reasonable structure, high degree of automation and high reliability of the entire line.

The barrel screw with European structure can greatly increase the extrusion volume and greatly improve the plasticization and mixing effect of raw materials.

The whole line adopts PLC control system to realize synchronization and automation.

Human-computer interface, intuitive operation, convenient and reliable.

The traction machine can choose the servo motor and control system, the traction is stable and has a wider traction speed range.

Chipless blade cutters and saw blade cutters are available for you to choose from.

Our PE pipe extrusion line can produce PE pipe size range from Ø16 to Ø2000mm.

PE pipes can be used for threading pipes, water supply, gas supply, drainage, liquid transportation, electrical conduits, etc.

Our PE pipe extruder can process different kinds of PO materials: PP, PPR, PERT, PB, PEX-B, etc.

We can provide different PE pipe extrusion lines: normal or high speed, single or multi-layer, single or double output (double output and four output are suitable for small pipe diameter).

Technical features:

Using advanced European technology and based on years of experience in plastic machinery research and development and production, our company has developed a high-efficiency and energy-saving PE pipe extrusion production line with advanced design, reasonable structure, high degree of automation and high reliability of the entire line.

The barrel screw with European structure can greatly increase the extrusion volume and greatly improve the plasticization and mixing effect of raw materials.

The whole line adopts PLC control system to realize synchronization and automation.

Human-computer interface, intuitive operation, convenient and reliable.

The traction machine can choose the servo motor and control system, the traction is stable and has a wider traction speed range.

Chipless blade cutters and saw blade cutters are available for you to choose from.

Main technical parameters (the following parameters are for reference only):