do you know what is wood plastic product?

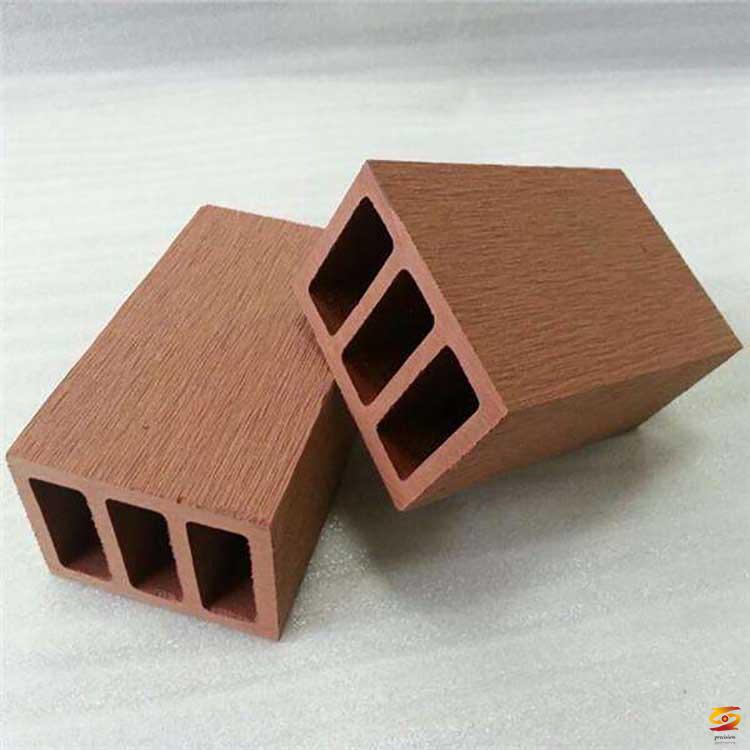

WPC composite material (new composite material)Wood-Plastic Composites (Wood-Plastic Composites, WPC) is a new type of composite materials that has been booming at home and abroad in recent years. Wood flour, rice husk, straw and other waste plant fibers are mixed into a new wood material, and then through extrusion, molding, injection molding and other plastic processing techniques to produce plates or profiles. Mainly used in construction materials, furniture, logistics and packaging industries. Plates that are formed by hot extrusion after mixing plastic and wood powder at a certain ratio are called extruded wood-plastic composite plates.

Chinese name Wood-Plastic Composites, foreign name Wood-Plastic Composites, WPC use building materials, furniture, logistics packaging, main features have water resistance, corrosion resistance, etc.

table of Contents

1 Main features

2 Material technology

▪ Scope of application

▪ Implementation standards

▪ Physical and chemical properties

3 How to call

main feature

The basis of wood-plastic composite materials is high-density polyethylene and wood fiber, which determines that it has certain characteristics of plastic and wood.

1) Good processing performance

Wood-plastic composites contain plastics and fibers. Therefore, they have similar processing properties to wood. They can be sawed, nailed, and planed, and can be completed using woodworking utensils. The nail holding force is significantly better than other synthetic materials. Mechanical properties are superior to wood materials. The nail holding force is generally 3 times that of wood and 5 times that of particle board.

2) Good strength performance

The wood-plastic composite material contains plastic, so it has a good elastic modulus. In addition, because it contains fibers and is thoroughly mixed with plastic, it has physical and mechanical properties comparable to hardwood, such as compression and bending, and its durability is significantly better than ordinary wood materials. The surface hardness is high, generally 2-5 times that of wood.

3) With water and corrosion resistance, long service life

Compared with wood, wood-plastic materials and their products are resistant to strong acids, alkalis, water, and corrosion, and do not multiply bacteria, and are not susceptible to worms or fungi. Long service life, up to more than 50 years.

4) Excellent adjustable performance

Through additives, plastics can undergo polymerization, foaming, curing, modification and other changes, thereby changing the density, strength and other characteristics of wood-plastic materials. It can also meet special requirements such as anti-aging, anti-static, and flame retardant.

5) It has ultraviolet light stability and good colorability.

6) Its biggest advantage is to turn waste into treasure, and it can be recycled 100%. Can be decomposed without causing "white pollution", it is a truly green and environmentally friendly product.

7) Wide source of raw materials

The plastic raw materials for the production of wood-plastic composites are mainly high-density polyethylene or polypropylene. The wood fibers can be wood flour, bran or wood fibers, and a small amount of additives and other processing aids are also required.

8) Can be made into any shape and size according to needs.

Material Technology Editor

With the research and development of wood-plastic composite materials, in addition to high-density polyethylene or polypropylene, there are also polyvinyl chloride and PS. The process has also been developed from the earliest single-screw extruder to the second-generation conical twin-screw extruder, to the parallel twin-screw extruder for preliminary granulation, and then the conical screw extrusion molding, which can make up for the difficulty of plasticization , Poor aging resistance, poor creep resistance, poor color consistency and durability and tensile strength. [1] After many years of research and development and accumulation of many new research institutes and Han Yong Plastics in China, the WPC materials manufactured can fully reach GB / T 24137 and ASTM D7031; ASTM D7032; Claim. [2]

Scope of application

One of the main uses of wood-plastic composite materials is to replace the application of solid wood in various fields. Among them, the most widely used is in construction products, accounting for 75% of the total wood-plastic composite products. The main places and uses of wood-plastic composite materials are shown in Table 1.3-1.

Table 1.3-1 Main use places and uses of wood-plastic composite materials [3]

Place

Category

The main purpose

Specification

Outside

Outdoor board

Lawn corridor, swimming pool edge, open-air corridor

According to user requirements

Flower box board

Flower box, tree pond, fence, trash can

According to user requirements

Decorative plates

Exterior wall decorative panels, sun visors, blinds

According to user requirements

Bench bar

Stool, chair strip, backrest strip, leisure table top

According to user requirements

Sign

Signs, signs, bulletin boards

According to user requirements

Structural timber

Column, beam, keel (can be set with metal parts)

Available in square, round and I-shape

Hydrophilic Paving

Wharf decking, water passages, near-water buildings

w 10-15cm h 2-3cm

Type (board) material

Planks, trails, bridges (solid or hollow)

w 10-15cm h 2-3cm

Profile (rod) material

Handrail, guardrail, fence, partition, lining

According to user requirements

Flower stand corridor

——

Complete building according to user requirements

Outdoor gazebo

——

Complete building according to user requirements

Open deck

——

Complete building according to user requirements

Simple parking room

——

Complete building according to user requirements

Inside the room

Floor

——

h 1.2-1.8cm

Top plate

——

According to user requirements

Wall skirt

——

According to user requirements

Bathroom board

——

According to user requirements

Door and window frame sets

——

According to user requirements

Indoor partition

——

According to user requirements

Sound insulation board (wall)

——

According to user requirements

Decorative lines

Various types of corner lines, side strips, inlays, decorative strips

According to user requirements

Executive Standard

LY / T1613-2004 extruded wood-plastic composite sheet

Physical and chemical properties

Should meet the requirements of Table 1.5-1

Table 1.5-1 Physical and chemical properties of wood-plastic composites

project

index

Moisture content (%) ≦

2

Hardness (HRR) ≧

58

Water absorption thickness expansion rate (%) ≦

1

Static bending strength (MPa) ≧

20

Flexural modulus (MPa) ≧

1800

Surface wear resistance (G / 100r) ≦

0.08

Low temperature drop hammer impact, the number of cracks (pieces)

1

State after heating

No bubbles. crack. Pockmark

Dimensional change rate after heating (%)

± 2.5

High and low temperature repeated dimensional change rate (%)

± 20.2

Screw holding force (N) ≥

Board surface

1000

Sheet metal

800

Weather resistance (MPa) ≥

Static bending strength

16

Chinese standards: GB / T 24137; GB / T 17657, etc.

Foreign standards: The more famous ones are: ASTM D7031; ASTM D7032; BS DD CEN / TS 15534-3, etc .;

Calling editor

The different names of "WPC" or "WPC" bring too much trouble to the production and user, especially for those who are new to the product. I think it ’s more appropriate to call it “plastic wood”.

There are four reasons:

The first is that the material is mainly used to replace wood, which is a kind of "wood" synthesized with plastic and wood fiber;

The second is that most of the wood fiber content of plastic wood products produced in China is greater than 50%, mainly wood;

The third is to express the meaning of using wood fiber as the basic raw material in the definition of the American standard, "wood" is the main body;

The fourth is the alias of this material at home and abroad, such as "plastic wood", "environmental protection wood", Japan's "Ein wood", etc., all emphasize "wood", so it is more reasonable to call it "plastic wood".

If you want to know more about it please do not hesitate to

contact me. WhatsApp:+86-15966835076.