Plastic building formwork, PP hollow building formwork production characteristics and professional market analysis

Plastic building formwork, PP hollow building formwork production characteristics and professional market analysis1. Introduction of plastic building templates

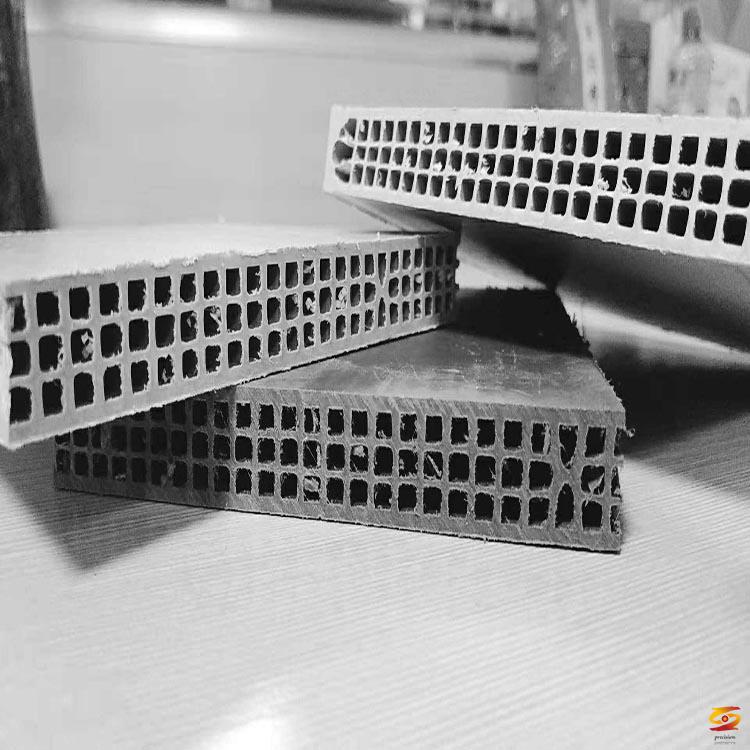

Plastic building template, PP hollow building template is a composite material extruded at a high temperature of 200℃. It is an energy-saving and environmentally friendly product and an important component of plastic building templates. It has a high turnover frequency (more than 30-50 times), a large temperature adaptation range, strong adaptability to specifications, and convenient construction. It can meet the requirements of various rectangular, cubic, L-shaped, and U-shaped building formwork. It has the functions of flame retardant, anticorrosion, water resistance and chemical resistance. Plastic building templates and PP hollow building templates have good mechanical properties and electrical insulation properties, and can have a long normal service life (more than 8 years). And it has the characteristics of good surface effect, light weight and high strength. It can also be 100% recycled and reused, which is in line with national environmental protection and circular economy policies.

Second, the plastic building template, PP hollow building template production process

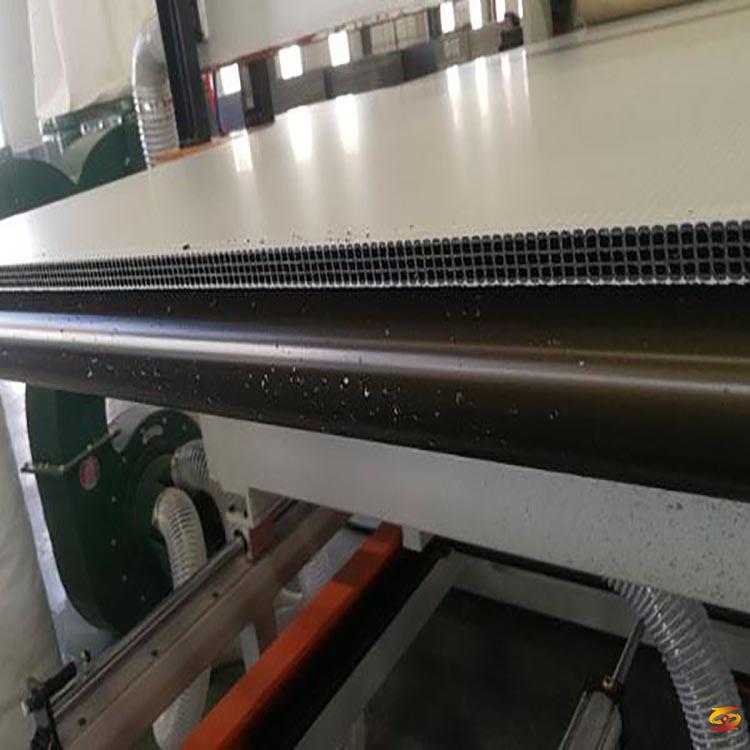

The raw materials (pp particles and fragments) are continuously sent to the PP hollow template extruder (integrated equipment) through the hopper, and the materials are heated to 160~170°C (automatic temperature controlled electric heating) under automatic stirring to soften them; This process will produce a small amount of organic waste gas G1 (calculated as non-methane total hydrocarbons) = the softened material is extruded and formed in the PP hollow template extruder, and conveyed to the cooling system through the conveyor belt to cool (indirect cooling, cooling water circulation, regular A certain amount of cooling drainage w1) is discharged to complete the shaping. After cutting, trimming and finishing, the above process of finished products will produce a certain amount of unqualified products 51 and scraps S2, which are comprehensively used after being crushed by the crusher.

Three, plastic building templates, PP hollow building templates performance advantages and characteristics

The quality of the formwork and the speed of installation (disassembly) directly affect the project quality and construction progress. The following table compares the performance indicators of several building templates:

Table 1 Performance comparison of several building templates

product type

Performance

Plastic building template, PP hollow building template

Aluminum template

All steel formwork

Bamboo wood glued template

Combined steel formwork

Wooden formwork

Flame retardant

Yes

Yes

Yes

no

Yes

no

Absorb water

And deformation

Does not absorb water

No deformation

Does not absorb water

No deformation

Does not absorb water

No deformation

Absorb water

Easy to deform

Does not absorb water

No deformation

Absorb water

Easy to deform

Demoulding process

easy

Moderate

Difficult

Moderate

Moderate

Moderate

Release agent

no

need

need

need

need

need

Corrosion resistance

excellent

good

good

good

good

good

repeat times

>50

>300

40

6~8

30~40

3~5

Recyclability

100% recycled

100% recycled

100% recycled

Not easy to recycle

Not easy to recycle

Not easy to recycle

Custom size

can

can

Can't

Can't

Can't

Can't

Bamboo and wood templates have fewer turnovers, plain wood and bamboo plywood templates are generally used 3 to 5 times, resource utilization is low, waste is serious, it is difficult to recycle templates after discarding, and the accumulation of a large number of templates will also affect the construction management progress ; The steel formwork is used more frequently, but the steel formwork has a larger proportion, which is 6~8 times that of the plastic building formwork and PP hollow building formwork. The construction operation is difficult, and the maintenance cost after deformation is high, which slows down the project progress and extension to a certain extent. The construction period increases the construction cost.

Plastic building template, PP hollow building template is a new green construction material in the 21st century. It has excellent overall performance and has the following advantages:

Plastic building template, PP hollow building template has high strength. Impact resistant, strong toughness, nailable, sawable and drillable, tightly spliced;

light in mass. Less labor is required for installation and disassembly, and the construction progress is faster, which can reduce the cost of formwork;

The surface is smooth. No need to use mold release agent, the surface is easy to clean, and the quality of the concrete surface can achieve the effect of clean concrete;

High turnover. Plastic construction formwork, PP hollow construction formwork turnover times can reach more than 50 times, can be used with steel (aluminum) frame for hundreds of times, the cost of single use is low, and it can save about 50% compared with bamboo and wood glued formwork;

Environmental protection and no pollution. The discarded template can be 100% recycled, and the secondary processing can make the finished template with the same quality as the original template, saving energy and protecting the environment.

Fourth, my country's plastic building templates, PP hollow building templates

With the rapid development of China's construction industry, the role of construction formwork in engineering construction has become more and more prominent, especially since the application of new formwork and scaffolding technology has been selected by the Ministry of Construction as one of the 10 new technologies for the construction industry to promote and apply. China's new plastic building templates, PP hollow building templates have made great progress in research, development, promotion and application, and a series of standard regulations have been issued successively. In 2006, China promulgated the "Green Building Evaluation Standard", and in 2013 issued the national standard of "Wood-plastic composite panel for building formwork", "plastic building formwork, PP hollow building formwork" industry standard and "green building action plan" officially landed As a result, green building actions in various regions are in full swing, and many provinces and cities have issued supporting policies for green building subsidies to vigorously promote the green process. In 2014, the "Green Building Evaluation Standard" was revised, and the industry standard "Building Plastic Composite Formwork Engineering Technical Regulations" of the Ministry of Housing and Urban-Rural Development passed the review.

4.1. Classification of market templates Faced with huge market demand and industrial policy guidance, many enterprises have swarmed in. The domestic plastic construction templates, PP hollow construction template products continue to diversify, such as: stereotyped reinforced plastic construction templates, PP hollow building template, strong plastic PP template, wood (bamboo, hemp, glass fiber, etc.) fiber reinforced plastic building template, PP hollow building template, hollow ribbed plastic building template, PP hollow building template, sandwich foam plastic building template, PP hollow building formwork, large engineering plastic formwork, steel frame plastic building formwork, PP hollow building formwork, wood-plastic composite formwork, etc.

Product categories: plastic steel template plastic steel template, plastic steel square wood, plastic steel yin and yang angle, plastic steel cylindrical template, plastic steel bridge template and other special-shaped templates. According to the material, it can be divided into: PVC, polypropylene (PP), polyethylene (PE), polycarbonate (PC), acrylonitrile-butadiene-styrene (ABS), high-density polyethylene (HDPE) According to the appearance, it can be divided into: solid board, hollow board, snap rib board, module assembly board, plastic square wood, plastic yin and yang angle.

1. The wooden formwork is the mainstream. The wooden formwork consumes a lot of wood, and the residual value of scrap is low. It is necessary to cut down forests, violate the protection of forests advocated by national policies, and need to apply mold release agents during use.

2. In recent years, aluminum formwork has appeared, and the cost is high. It is mainly leased, and a mold release agent is also used. 3. Now using aluminum frame plastic building templates, PP hollow building templates appear, the cost is lower than aluminum templates, no mold release agent, easy to recycle, the operating mode is the same as aluminum templates, mainly leasing.

4. Plastic building templates, PP hollow building templates are mainly PVC, PP modified solid and hollow, easy to recycle, can be used up to 50 times, and can be recycled and reused templates.

4.2. Quality status of plastic building templates and PP hollow building templates

Rugged development has brought plastic building templates. PP hollow building template companies are mostly small and medium-sized, which has failed to form effective large-scale production. The product technology research and development capabilities are relatively insufficient, resulting in uneven product quality. The cost of production links and The cost of product use has not been effectively improved. The performance characteristics of plastic building templates and PP hollow building templates are not fully reflected in engineering applications, resulting in a low market share of plastic building templates and PP hollow building templates in the domestic market. 1. In the past two years, there have been many emulations, no technical support, core formulas have not reached the standard, and there are many problems in the marketing model. The after-sales service cannot keep up, etc. need to be improved and improved. 2. At present, all plastic construction formwork and PP hollow construction formwork equipment in the industry can be fully loaded to produce 8 billion annual sales, which is far from the 570 billion wood formwork market. 3. Only by adhering to quality first, constantly improving the formula, and constantly improving product quality can we meet the needs of different customers, go further, and be recognized and accepted by the market. 4.3. Plastic building templates, PP hollow building template market status According to market research, the annual consumption value of building templates in the country is 570 billion. Plastic building templates and PP hollow building templates have just accounted for 5% of the market. 1. The small builder's one-time investment is too high to accept. 2. The purchase intention of central enterprises and state-owned enterprise builders is obvious, and they can accept the use of plastic construction templates and PP hollow construction templates to replace wooden templates and aluminum templates. However, the installment payment method cannot meet the payment method for manufacturers with too small capital scale. 3. The lease model is easy for any builder to accept, 0.2-0.25 yuan per square meter per day, an average of 1.67 square meters for a template, and a monthly rent of 10-12 yuan. However, manufacturers are usually small in scale and have difficulty in capital turnover, so they can only invest in the leasing market. Compared with the sales model, the leasing model is currently the only option for dealers and manufacturers. The market can only be opened with the leasing model as a breakthrough to occupy the market. 4. Export orders have gradually increased and foreign acceptance has been relatively high.

4.4. Foreign plastic building templates, PP hollow building templates are developed in countries with relatively developed plastic industries, such as Germany, North America, Japan, and South Korea. Plastic building templates have begun large-scale production and application as early as a few decades ago, gradually replacing the waste of forest resources. Wooden formwork and steel formwork with high production energy consumption. Foreign plastic building templates, PP hollow building template companies are mainly concentrated in Europe, North America and South Korea and Japan in Asia. The number of enterprises is not large, but the production scale is relatively large, and the production technology is more advanced than domestic ones. The products of plastic building templates and PP hollow building templates are more diversified. Foreign plastic construction templates, PP hollow construction template products mainly include steel (aluminum) frame plastic construction templates, PP hollow construction templates, engineering plastic large templates, GMT construction templates, hollow plastic construction templates, PP hollow construction templates, foam insulation plastic construction templates , PP hollow building formwork, plastic formwork, decorative formwork (liner), combined plastic building formwork, PP hollow building formwork, etc., can be widely used in wall, floor, column and other building construction. There are also special-shaped plastic building templates processed into various shapes and surface patterns, and PP hollow building templates. The products have rich finishes and diverse shapes. The shaped concrete has unique shapes and surface textures. In order to enhance the strength and rigidity of plastic building templates, PP hollow building templates, improve the turnover times of plastic building templates, PP hollow building templates, and improve the quality of formwork products. There are usually the following ways: 1) Adding reinforcing fibers in the preparation process of plastic building templates, PP hollow building templates; 2) Plastic building templates, PP hollow building templates are coated with reinforcing layers or made of sandwich plastic building templates, PP hollow Building templates; 3) Plastic building templates, PP hollow building templates are added with ribs or made of hollow ribbed plastic building templates, PP hollow building templates. In addition, foreign plastic building templates, PP hollow building templates have formed a variety of formwork systems, such as Slovenia EPIC Group company developed EPIC plastic building templates, PP hollow building template systems, Vietnam FUVI plastic building templates, PP hollow building template companies developed All-plastic construction formwork, PP hollow construction formwork system, Italy GEOTUB plastic construction formwork, PP hollow construction formwork company developed plastic flat formwork and arc-shaped formwork, which can be used for various concrete structures such as walls, slabs, beams and columns. However, my country's plastic building templates and PP hollow building templates have not yet formed a system. Most of the companies only produce plastic flat panels, which are mainly used for horizontal templates in construction and bridge engineering.

4.5. Plastic building templates, problems facing the development of PP hollow building templates

In summary, the analysis of the index basically reflects that the current development of the plastic building template and PP hollow building template industry is on the rise, but there are still some problems in the development process of the plastic building template and PP hollow building template companies.

First, there is no uniform standard for development, and product quality varies. With the rapid development of the plastic building template and PP hollow building template industry, more and more companies have entered the market, and the vicious competition of peers has caused some "sub-filled" products to flow into the market, affecting the healthy development of the industry.

Second, the structure of the industrial chain needs to be optimized urgently, and the contradictions between the upstream and downstream industrial chains are prominent. Among them, the quality of raw materials is difficult to control, and the price increase trend is obvious, which has caused the cost of products of manufacturers to rise and the market price to rise slowly.

Five, plastic building templates, PP hollow building template market blue ocean in the future

5.1 Market size

With the continuous promotion of the national green building and the increasingly hard environmental constraints, the promotion of the use of green building materials such as plastic building templates and PP hollow building templates in the construction field is an inevitable trend. The future of the plastic building templates and PP hollow building template markets must be a blue ocean However, to enter this "blue ocean", you must also be clearly aware of the current status of the plastic building formwork and PP hollow building formwork market and solve existing problems before you can set sail. 1. According to market surveys, the annual consumption of building templates in the country is 570 billion yuan. Plastic building templates and PP hollow building templates have just accounted for 5% of the market. The market potential is huge. 2. According to the national real estate statistics, the construction area is 20 yuan per square meter, and the construction area *3.1 times needs to be supported by the template. The price of the current wooden template is about 50 yuan. It takes 6-8 times, each time 6-8 yuan, that is, the template value of one square meter of construction area is 3.1*(6-8), about 20 yuan. 3. There are templates for towns, bridges, highway underground pipe corridors, etc.

At present, the development of my country's plastic building template and PP hollow building template market is still in its infancy, and the product quality is uneven, which to some extent misleads consumers and hinders its promotion and application. To solve my country's plastic building templates, the promotion and application of PP hollow building templates mainly starts from the following aspects:

1) The design, production, construction and leasing of the formwork must be strictly controlled. According to the actual construction conditions in China, the fast-growing foreign plastic building formwork and PP hollow building formwork technology are selectively absorbed. "Take the essence, "Remove its dross" and realize "for my use"; 2) Collect and analyze the first-line feedback information of engineering construction, and continuously improve product design through technological innovation; 3) Research and development of new plastic building templates with independent intellectual property rights, PP hollow buildings Template products, build an integrated platform for production, education and research, and apply intellectual property rights to actual production in a timely manner.

5.2 National policy support for green environmental protection industry

In recent years, with the establishment and improvement of China's green and low-carbon circular development economic system, the concept of green development has been deeply rooted in the people's hearts. The state has promoted and supported the green building materials industry, and has continued to promote development policies for the development of hollow plastic building templates and PP hollow building template industries. Provides strong policy support.Guiding Opinions on Building a Market-Oriented Green Technology Innovation System” (Fa Gai Huan Zi [2019] No. 689), the opinion pointed out that it is necessary to speed up the establishment of the enterprise as the main body, deep integration of production, education and research to form a research and development, application promotion and industrial development linkage New situation of integrated green technology innovation. Plastic building template, PP hollow building template industry should adhere to the integration and innovation of green technology in technology research and development, product upgrade, promotion and application.

Second, the General Office of the Central Committee of the Communist Party of China issued the "Guiding Opinions on Promoting the Healthy Development of Small and Medium-sized Enterprises", in which the "one enterprise and one policy" service has a role in promoting the development of plastic building templates. Important role. The improvement of the middle and lower enterprise financing policies and fiscal and tax support policies in the comments is of great significance for plastic building templates, PP hollow building template SMEs in cracking financing difficulties and expensive financing and tax burden reduction.

The third is that the Beijing Municipal Housing and Urban-Rural Development Commission issued a notice to solicit opinions on the "Catalogue of Beijing Prohibited Use of Construction Materials (2018 Version)". The notice stated that 77 kinds of construction materials will be banned. Among them, bamboo and wood plywood templates have poor water resistance and few turnovers, and waste of resources is intended to be banned.

Fourth, the “Guiding Opinions on Accelerating the Development of Renewable Resources Industry” (Ministry of Industry and Information Technology (2016) No. 440) jointly issued by the Ministry of Industry and Information Technology, the Ministry of Commerce, and the Ministry of Science and Technology The development of high-value, high-value, specialization and clustering put forward higher requirements. For plastic building templates, the PP hollow building template industry plays an active guiding role in strengthening product green innovation, recycling, regional promotion, and industrial cluster development, and promotes plastic building templates. PP hollow building template industry is specialized and clustered High-quality development.

Fifth, implement the “Thirteenth Five-Year Plan for Building Energy Conservation and Green Building Development” issued by the Ministry of Housing and Urban-Rural Development (Jianke [2017] No. 53), and realize that the proportion of green buildings in cities and towns in the country will account for more than 50% of new buildings in 2020. The target of the application ratio of medium-green building materials exceeds 40%. This provides an important development opportunity for the development of the plastic building template and PP hollow building template industry. As a new type of green building material, the hollow plastic building template and PP hollow building template meet the national green building material standards in product materials and construction applications.

5.3 Market prospect

At present, some financial companies and large enterprises have begun to understand and pay attention to the plastic building template. The PP hollow building template market has already been in contact and has the intention to enter the production leasing model. Some large enterprises with strength and capital understand the market trends and investigate the project. The production enterprises are based on high standards and quality requirements, with financial support, and they have a leasing model and an aluminum frame combined leasing model. The prospects are very good. Cooperating with the entry of the state-owned enterprise construction enterprises along the “Belt and Road”, the main infrastructure projects are the main ones. They are satisfied with the use of plastic building templates and PP hollow building templates. Export orders have gradually increased, and foreign acceptance has also gradually increased. The next 3-5 years will surely achieve some large plastic building templates, PP hollow building template companies. In addition, the market's preference and acceptance are getting higher and higher. At present, some bidding documents have specified the use of plastic building templates, PP hollow building templates. China continues to increase its protection of the ecological environment and has completely stopped commercial logging of natural forests. At the same time, actively advocate the concept of energy saving, environmental protection and green building. It is an inevitable trend to promote the use of green building materials such as plastic building templates and PP hollow building templates in the construction field. "Replacing wood with plastic" is not only a slogan, but also an important measure in response to the country's efforts to strengthen ecological civilization. In the long run, promote the efficient use of resources, energy saving and consumption reduction, and then achieve green and sustainable development. Beijing has begun to ban the use of wood glue and building templates. In the context of rapid social progress, the market scale of plastic building templates in the construction field is increasing. And as the construction industry now has higher and higher requirements on the formwork technology, the reliable plastic construction formwork gradually replaces the traditional formwork and successfully catches up with the golden opportunity of development. It is precisely because of the environmental protection advantages of plastic building templates that it can be needed by today's advocating building a conservation-minded society and become a new generation of "darlings" of the construction industry.

If you want to know more about it please do not hesitate to

contact me. WhatsApp:+86-15966835076.