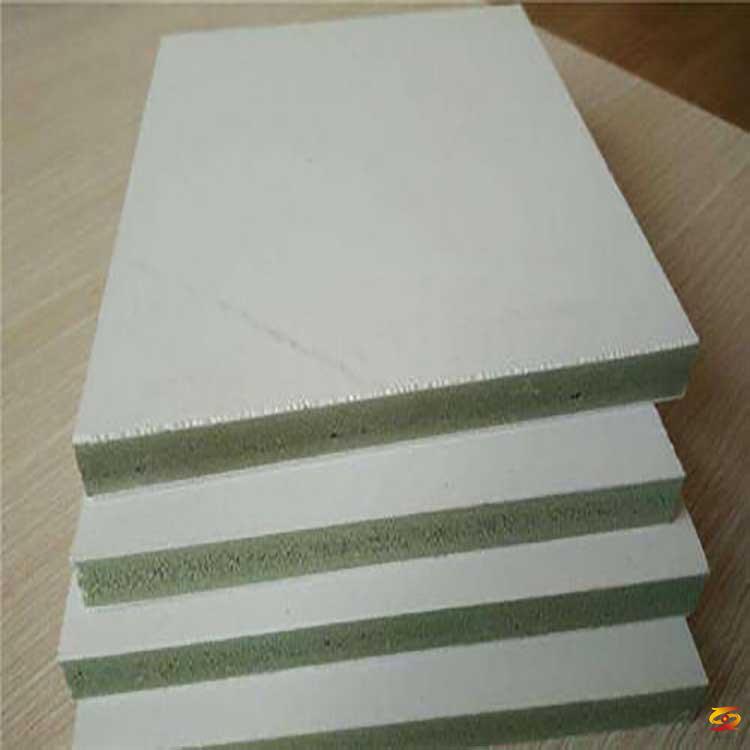

PVC wood plastic foam building template raw material formula and operation precautions

PVC wood plastic foam building template raw material formula and operation precautions

If you want to know more about it please do not hesitate to

contact me. WhatsApp:+86-15966835076.