PP packing belt Basic knowledge

PP packing belt Basic knowledgePP strapping, scientific name polypropylene, is one of the lighter common plastics. The main material of PP strapping is polypropylene brushed grade resin, because of its good plasticity, strong breaking force, bending resistance, light weight, easy to use and other advantages , The processed strapping has been widely used in various fields. PP stands for polypropylene. There are many polypropylene grades. The production of packing tape (the best effect) uses the polypropylene raw material of grade T30S. PP packing belt appearance: translucent to opaque, transparent film. Flammability: Combustible in flames. After leaving the flame, slowly extinguish or continue to burn. When burning, the upper end of the flame is yellow, and the lower end is blue; there is a phenomenon of melting and dripping. Smells of paraffin.

Chinese name PP packing tape scientific name polypropylene material polypropylene drawing grade resin has good plasticity and strong breaking tension

table of Contents

1 Features

2 Classification

3 Color types

4 Material

5 Use

6 Production process

7 Production process

8 Tensile parameters

9 Identification

10 Industry characteristics

Features

1. Polypropylene (PP) is the main raw material, material: polypropylene wire drawing grade resin, because of its good plasticity, it is broken and drawn

Strong strength, resistance to bending fatigue, small density, good tensile impact performance, easy to use and other advantages, are now in various fields

In a wide range of roles.

2. Suitable for all kinds of strapping machines in all walks of life (semi-automatic, fully automatic, manual baler)

3. Extra strong adhesion, high pulling force, light weight, corrosion resistance, beautiful appearance and high grade

4. Bright color, there are many colors such as yellow, white and black, you can choose

5. According to customer requirements and samples, we can produce special packing belts such as printing and icon printing.

Category Editor

1. The polypropylene raw material for producing strapping is transparent and granular, so PP strapping can be classified as:

Transparent PP packing tape

Translucent PP packing tape

Color PP packing belt

2. According to the proportion of polypropylene used in the production of packaging belts, PP packaging belts can be divided into:

New pure material PP packing belt

Pure material (recycled material) PP packing belt

Ordinary sandwich PP packing belt

3. According to the purpose of use, it can be divided into

Fully automatic PP packing belt

Semi-automatic PP packing belt

PP packing tape by hand

Flexible PP strapping

4 According to the machine used

Machine packing belt

Packing tape for hand

Color type

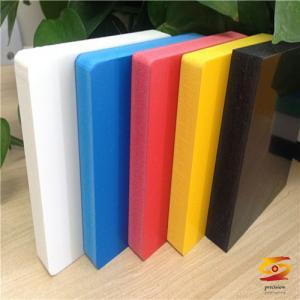

White, red, yellow, blue, black and other colors.

Material editing

Polypropylene brushed grade resin has been widely used in various fields because of its good plasticity, strong tensile strength at break, bending fatigue resistance, low density, good tensile impact performance, and ease of use.

use

Used for carton packing, used with automatic packing machine.

Production Process

The first is the temperature control of the extruder (generally 250℃~280℃). The next step is cooling. After the material is taken out of the machine head, the temperature is very high. It is necessary to immediately enter the water to cool, because the isotactic polypropylene is prone to generate a crystalline structure under the condition of rapid cooling, and the molecular structure of the crystalline is relatively loose. It is easy to stretch the orientation and obtain high quality products. Then the stretching, the purpose of stretching is to increase the longitudinal strength of the strapping and reduce the elongation. Stretching must be carried out in boiling water, generally using a stretch. Finally, there is embossing. The stretched baling belt passes through two patterned pressing rollers and is pressed onto the pattern. Its function is to increase friction during use, without slipping, and it looks beautiful from the outside.

Production Process

PP packing belt production process: plastic granule melting---pressure belt----forming----cooling-----wrap-up-packaging-in storage. PP strapping is a packing material with a mesh structure produced by heating, melting, stretching, and cooling of polypropylene. The basic parameters that affect the quality of strapping are tension, length, curvature, and elongation. In the case of the same tension and other parameters, the longer the length, the lower the cost. PP packing belt introduces four of the world's most advanced packing belt production lines, using processing technology to produce high-strength, high-quality, environmentally friendly 3,000 meters of new material packing belt, the unit price per meter is much lower than domestic recycling belts and similar imported belts Unit price.

The packing belt is made of polypropylene through heating, melting, stretching, and cooling. It is a net-shaped packaging material. The basic parameters that affect the quality of the packing belt are tension, length, curvature, and elongation. In the case of the same tension and other parameters, the longer the length, the lower the cost. Jinan Samsung introduced four of the world's most advanced packaging belt production lines, using processing technology to produce high-strength, high-quality, environmentally friendly 3,000 meters of new material packaging belts, the price of packaging belts per meter unit cost is much lower than domestic recycling belts and similar The unit price of the import belt reduces the cost by 120%.

Tensile parameters

1. 12mm wide and 0.6mm thick pure PP packing tape with breaking tension> 1000N elongation: <20%

2. 13.5mm wide and 0.6mm-0.8mm thick pure PP packing tape with breaking tensile strength: 1000N-1500N elongation: <20%

3. Pure material PP strapping with 15.5mm width and 0.6mm-0.8mm thickness, its breaking tensile force: 1500N-2000N elongation: <20%

4. 19mm wide, 0.6mm-0.8mm thick, pure PP packing tape, its breaking tensile force: 2000N-3000N elongation: <20%

Identification

There are the following standards for judging the quality of PP strapping belts:

1. The strapping belt should have good toughness. Fold the PP strapping belt repeatedly, and the toughness is easy to break. For the pattern problem, the pattern must be beautiful, and do not appear biased.

2. The quality of PP packing machine belt is generally white (other colors are bright), because these are not easy to mix with old materials.

3. The strapping straps should have glossiness. Such strapping straps are generally made of all materials. The tension is stable. If the baler is mixed with powder, the gloss will be greatly reduced.

4. The width of the strapping belt, the width error is generally plus or minus 0.3mm. During the production of such baler belts, the blanking is uniform, and the quality will be relatively uniform, and there will be no good or bad conditions.

5. Some baler belts have brand new materials on the outside, with filling material in the middle (very poor), as long as the cut section is cut and you can see the black heart inside is poor quality.

The color of the strapping belt is not easy to say. The transparent strapping strap is the best strapping strap. The quality of the baler belt depends entirely on the purity of the polypropylene. The higher the purity of the polypropylene, the better the tension of the baler belt.

Industry characteristics

Packaging belt in paper industry: clean, tidy but easy to wrinkle; good corrosion resistance and non-rust high-quality elasticity, easy to operate.

Packing tape used for canned packaging: can not withstand strong impact, squeeze, drop, etc.; the ductility is better than that of steel tape with appropriate elasticity, maintaining good tear strength.

Aluminum ingot industry packing belt: It is easy to chemically react with strong acid and alkali, water; waterproof and corrosion-resistant and tension-retaining is better than steel belt.

Packaging belt in the building materials industry: rigid and heavy; good ductility is not easy to crack, the density is 1/6 of the steel belt, which is more economical than the steel belt.

Ceramic industry packing belt: easy to be brittle, can not withstand strong impact, squeeze, drop, etc.; good holding performance of tension, small degree of relaxation, good impact resistance, suitable for long-distance long-term transportation.

Packaging belts in the wood industry: the edges are easily scratched; the corrosion resistance and the waterproof surface are smooth, which is beneficial to protect the edge density: 1/6 of the steel belt.

Bundling tape in the fiber and fiber industry: soft, slack and easy to deform; good tensile strength, not easy to break, moderate elastic strength, not easy to slack.

Packing belt in the steel pipe industry: easy to roll, and can react with strong acids and alkalis; waterproof and corrosion-resistant compared to steel belts, it is elastic but not easy to extend too much.

If you want to know more about it please do not hesitate to

contact me. WhatsApp:+86-15966835076.