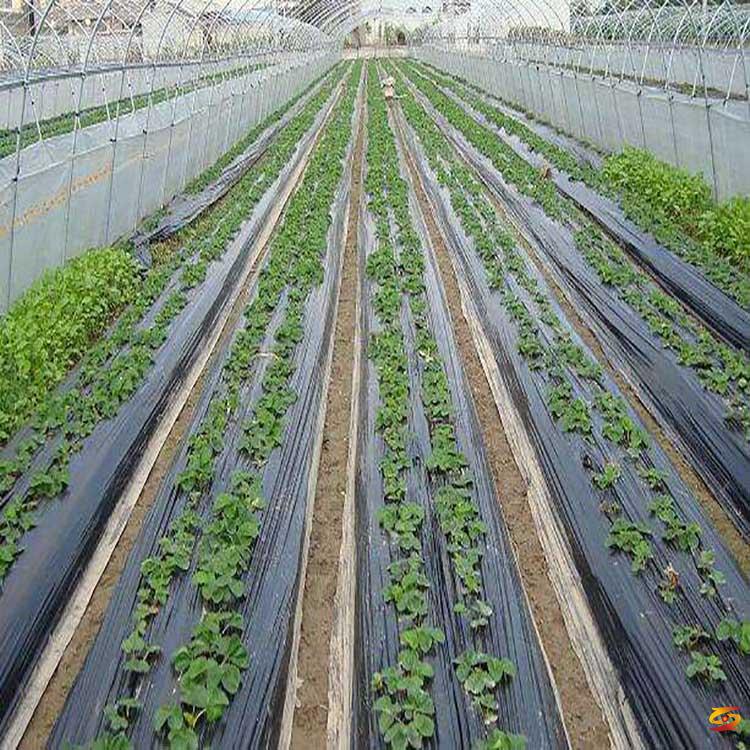

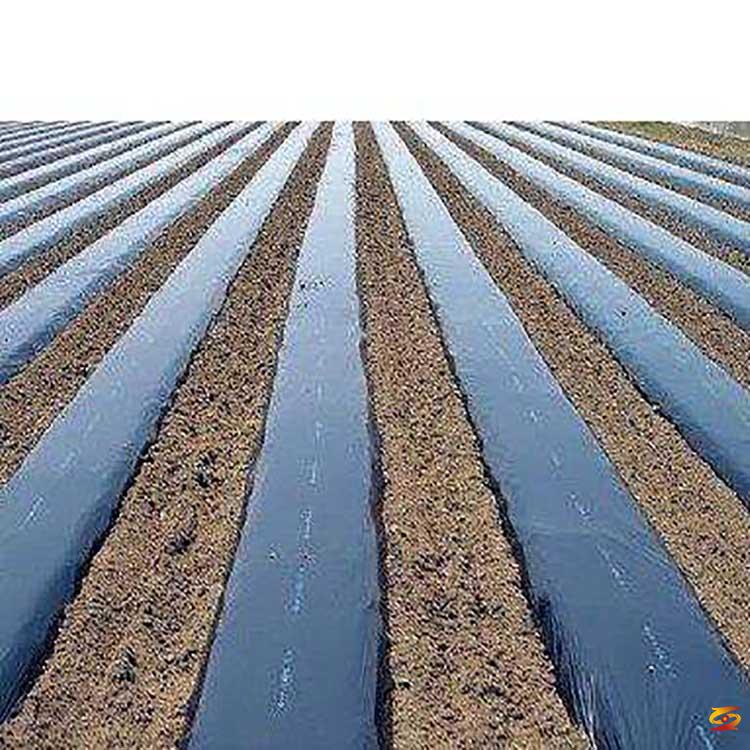

Plastic film mulch has the effect of increasing ground temperature and maintaining moisture in winter and spring

The benefits of spreading plastic film are many! Common Misunderstanding of Paving Film (Case Sharing)Plastic film mulch has the effect of increasing ground temperature and maintaining moisture in winter and spring.

1. Benefits of mulching film

1. Increase soil temperature

Plastic film mulch has the effect of increasing ground temperature and maintaining moisture in winter and spring. The temperature of the cultivated soil layer covered with plastic film generally raises the soil temperature by 2 ℃ -3 ℃ compared with the open field, which can promote the early emergence and early development of vegetables, so that the spring can be planted or planted in advance 10-20 days in advance. It should be noted that the warming effect of different color mulches is different, and the colorless film has good warming effect, while the silver-gray film basically does not increase the temperature, the black mulch does not transmit light, the ground temperature rises slowly, and the grass is pressed. It is mainly used in low humidity fields, Cultivation of vegetables that are prone to weeds.

Because the effect of cooling and weeding is better than that of black mulch in high temperature in summer, it is mainly used for heat-resistant cultivation of vegetables and melons in summer and autumn. It has the functions of cooling, water retention, gloss enhancement, and weed control. Silver-gray mulch, also known as aphid-proof mulch, is used to cover cultivated cucumber, tomato, watermelon, bell pepper, celery, lettuce head, spinach, and tobacco to obtain good results. In order to save costs, 6-8 silver-grey strips with a width of 2 cm are printed uniformly in the longitudinal direction of the transparent or black mulch cultivation site, which also has the effect of avoiding aphids and preventing virus diseases.

2. Restrain the drastic change of soil temperature

Covering the film in summer can suppress the rise of soil temperature, and covering the film in winter can suppress the fall of soil temperature.

3. Improve fertilizer utilization and increase soil nutrition

The mulching film can prevent the sun and rain from dropping, so that the fertilizer will not be lost, and at the same time, it can adjust the soil temperature and strengthen the absorption capacity of the plant root system. The improved soil temperature and water conditions are conducive to the activities of microorganisms, and promote the decomposition of soil organic matter and minerals, and increase soil nutrients. Therefore, plastic film mulching can give full play to the fertilizer effect.

4. Improve the physical properties of the soil

The bulk density of the soil covered by the plastic film is smaller than that of the uncovered, and the rainfall makes the soil oxygen content higher than the open field, which is beneficial to the growth of plant roots. At the same time, due to less soil erosion, it can prevent soil compaction and improve soil physical and chemical properties.

5. Reduce water evaporation, reduce field humidity, reduce disease occurrence, and also have obvious water retention effect.

6. Increase light effect

For example, the reflection of the transparent plastic film itself and the small water droplets attached to the plastic film increase the reflected light near the surface, effectively changing the light conditions during the growth period of the crop, increasing the photosynthesis intensity of the crop and prolonging the photosynthesis time, thereby increasing In addition to light and yield and accumulation of organic matter.

7. Prevent soil salinization

After the mulch is covered, because the movement of soil water moves from bottom to top, the topsoil has a high water content, which relatively reduces the soil salt content, thereby playing a role in salt suppression.

8. Inhibit the growth of weeds and reduce the harm of pests

Due to the reflective properties of the plastic film, silver has a repellent effect on aphids, which can greatly reduce the occurrence of viral diseases.

9. Promote the early listing of crops

Because the mulching film regulates the underground part and the above-ground part of the plant and promotes the growth, the cultivated crops enter the product formation period earlier, especially increasing the early yield of the cultivated crops in winter and spring, thus also increasing the total output.

2. Common Misunderstandings of Paving Film (Case Sharing)

Plastic film mulching is a vital agronomic measure in agricultural production. It plays a prominent role in regulating the ground temperature, retaining water and fertilizer, greatly extending the crop cultivation period, saving agricultural water, improving the ability to fight agricultural disasters, and ensuring Stable and increased crop production.

In addition, the plastic film also has the effects of improving the physical and chemical properties of the soil, inhibiting the growth of weeds, and reducing disease. However, not all farmers use mulch film, especially in the production of greenhouse vegetables, the mulching method is unreasonable, which is an important reason for affecting the growth of vegetables.

Case 1: The mulch is close to the base of the stem and the dead tree is severe

Recently, the bell pepper planted by vegetable farmer Master Li has a large area of dead tree phenomenon. The base of the stem rots and becomes dark brown, soaking in water. The reason is that the humidity at the base of the stem has been relatively high. As the temperature gets warmer, Phytophthora infestans easily infects the stalks of sweet pepper, causing "black stems". It turned out that when Master Li covered the mulch, the mulch and the stalk were close together. When the temperature was high, the water evaporated from the soil condensed into a bead on the mulch and flowed down the base of the stem. The high-temperature and high-humidity environment has caused a severe occurrence of sweet pepper blight.

Improper mulching of plastic film is an important reason for the occurrence of epidemic diseases. Vegetable farmers are reminded here to remember that when mulching plastic film, they should not be close to the vegetable stalks. It is recommended not to cut the mulch film with a blade as much as possible, but to pick the mulch film with your fingers, to ensure that the mouth is larger and will not bridge, generally 5-8 cm in diameter is appropriate. In the high temperature stage, roll up the two sides of the plastic film to prevent the ground temperature from being too high; when the temperature drops, pull the plastic film away, and use the graft clip to clamp the two adjacent plastic films so that the plastic film does not touch the stem.

Case 2: Covering the ground with plastic film covering the whole shed, affecting root growth

The spring stubble tomatoes planted by Master Yuan this year are weak, with thin stalks and yellowed leaves, and the phenomenon of falling flowers and fruits is severe. Through field interviews, technicians found that the film covered by Master Yuan was close to the ground, which affected the gas exchange between the soil and the air. Especially after watering, the soil permeability was poor, resulting in obstruction of root breathing, poor root growth, and absorption of nutrients. If the ability is weakened, tomatoes will naturally grow weaker.

Many vegetable farmers directly cover the plastic film with the plastic mulch when covering the plastic film. Like Master Yuan, the operation film is closely attached to the ground after being stamped on countless times, and it will also press the plastic film when watering the planting line. It seriously affects the air permeability of the soil and hinders the respiration of the root system of vegetables, resulting in dysplasia of the roots. Experts suggest that it is best to use steel wire or bamboo poles to support the plastic film, one every 50 cm, covering the plastic film from the south to the north, so that watering under the film can be achieved, which improves the permeability of the soil. It makes it difficult for moisture to volatilize outside, which reduces the humidity in the shed; and the operation line is best to cover the crop straw, which not only raises the ground temperature, but also regulates the humidity in the shed.

Case Three: Autumn stubble vegetable mulch covered too early, is not conducive to deep rooting

Recently, as the temperature has dropped, vegetable farmers planting cucumbers are using the "punch method" to step up to cover the plastic film. It is carried out on a sunny afternoon. At this time, the cucumber stems and leaves have low water content and are relatively soft, and it is not easy to break the stems when mulching. In general, one person pulls the mulch axis at the back wall, and the other person holds the mulch at one end and pulls it from north to south. The mulch must be tightened and flattened without wrinkles. After the mulch is flush with the planting line, use soil around the mulch Compact and compact the plots with more weeds. After pressing the membrane, start to punch holes one by one and straighten out the cucumbers.

Experts suggest that in greenhouse vegetable cultivation, the time of covering the plastic film should be determined according to the specific climatic conditions. For example, after the autumn stubble cucumber is planted, the outside temperature is high. If it is covered with plastic film immediately, on the one hand, it will be prone to stuffy roots due to the excessive temperature increase of the plastic film; Growing can cause failure of squatting seedlings, and it is difficult to cultivate strong seedlings and strong trees. Therefore, it is recommended to cover the plastic film according to the specific weather conditions. Generally, it is necessary to cover the plastic film after 15 days of planting, which is conducive to planting the seedlings under the root system.

Case 4: Cover the mulch only in the operation line, completely wrong

When I visited, I also found that the sweet peppers grown by many local vegetable farmers only covered the operation rows in the shed, but the planting rows did not cover the plastic film. However, this approach not only did not give full play to the advantages of mulching, but also highlighted the disadvantages, and the effect was very poor. In the production of greenhouse vegetables, the most important role of mulching is to reduce the humidity in the greenhouse and reduce the occurrence of diseases. The practice of covering the plastic film and not covering the planting row is not conducive to reducing the humidity in the shed, because when the vegetables are watered, the planting row is most of the time, and the planting line does not cover the film to reduce the air humidity. To what extent, it can not play the role of thermal insulation. The disadvantages of covering the plastic film in the operation line are also obvious, which greatly reduces the soil permeability in the operation line and affects the growth and development of the root system.

If you want to know more about it please do not hesitate to

contact me. WhatsApp:+86-15966835076.