Description

Introduction

The PET Foam Sheet Machine represents cutting-edge technology in the sustainable materials manufacturing sector, designed specifically for producing high-performance Polyethylene Terephthalate (PET) foam sheets and boards. This advanced equipment transforms both virgin and recycled PET materials into lightweight, high-strength structural foam products that serve critical applications across multiple industries. As environmental regulations tighten globally and demand for sustainable materials increases, PET foam sheet production technology has emerged as a key solution for manufacturers seeking eco-friendly alternatives to traditional materials.

Technical Structure and Components of PET Foam Sheet Machine

Core System Components

The modern PET Foam Sheet Machine integrates several sophisticated systems working in harmony to deliver consistent, high-quality foam products. The primary components include:

- Raw Material Processing System

- Drying and crystallization units that reduce moisture content to below 50ppm

- Precision blending equipment for mixing PET with foaming agents and additives

- Automated feeding systems ensuring consistent material supply

- Recycling processing units capable of handling post-consumer PET waste

- Extrusion System

- Twin-screw extruders with specialized screw designs for PET processing

- Secondary extruders for enhanced mixing and pressure control

- Melt filtration systems removing impurities for superior product quality

- Melt pumps stabilizing pressure and flow rates for consistent output

- Foaming System

- Chemical foaming agent injection units with precise dosing control

- Physical foaming capabilities using supercritical CO₂ or N₂

- Reactive extrusion technology combining chemical reactions with physical foaming

- Multi-zone pressure control systems managing the foaming process

- Forming and Cooling System

- Specialized die designs accommodating foam expansion characteristics

- Calibration equipment ensuring dimensional accuracy

- Multi-stage cooling roller assemblies with temperature gradient control

- Haul-off systems maintaining consistent thickness and width

- Cutting and Post-Processing System

- Automated four-edge CNC cutting machines for precise dimensioning

- Stacking systems for efficient material handling

- Surface treatment equipment for specialized applications

- In-line quality monitoring systems ensuring product consistency

- Control System

- Advanced PLC automation controlling the entire production line

- User-friendly HMI interfaces for operator interaction

- Real-time parameter monitoring and data logging capabilities

- Remote monitoring and control options for enhanced operational flexibility

Technical Features

The state-of-the-art PET Foam Sheet Machine incorporates several technological innovations that set it apart:

- Reactive Extrusion Technology: Combines chemical reactions with physical foaming processes

- Dual-Stage Extrusion: Enhances mixing uniformity and product quality

- Precision Temperature Control: Multiple independently controlled heating/cooling zones

- High Automation Level: Fully automated operation from raw material handling to finished product packaging

- Adaptable Processing Capability: Handles both virgin and recycled PET materials

- Energy-Efficient Design: Optimized for reduced energy consumption

- Modular Construction: Facilitates maintenance and future upgrades

Production Process Flow

The production of PET foam sheets follows a sophisticated process flow that ensures consistent quality and performance:

1. Raw Material Preparation

The process begins with careful preparation of raw materials:

- Material Selection: Either virgin PET resin or recycled PET flakes

- Drying Process: Thorough drying to moisture levels below 50ppm

- Crystallization: Non-crystalline PET undergoes crystallization treatment

- Additive Preparation: Foaming agents, nucleating agents, chain extenders, and stabilizers

2. Extrusion and Foaming

The core of the production process involves sophisticated extrusion and foaming:

- Primary Extrusion: Material feeding, melting (260-280°C), and initial mixing

- Additive Incorporation: Precise addition of foaming agents and modifiers

- Pressure Building: Establishing optimal system pressure for controlled foaming

- Foaming Mechanism: Either chemical foaming agent decomposition or physical gas injection

- Pressure Release Control: Carefully managed pressure reduction triggering foam formation

3. Forming and Cooling

The foamed material undergoes precise forming and cooling:

- Die Forming: Specialized die shapes the expanding foam

- Initial Calibration: Dimensional stabilization immediately after die exit

- Controlled Cooling: Multi-stage cooling with temperature gradient management

- Dimensional Stabilization: Maintaining precise thickness and width during cooling

4. Post-Processing

Final processing ensures product quality and specification compliance:

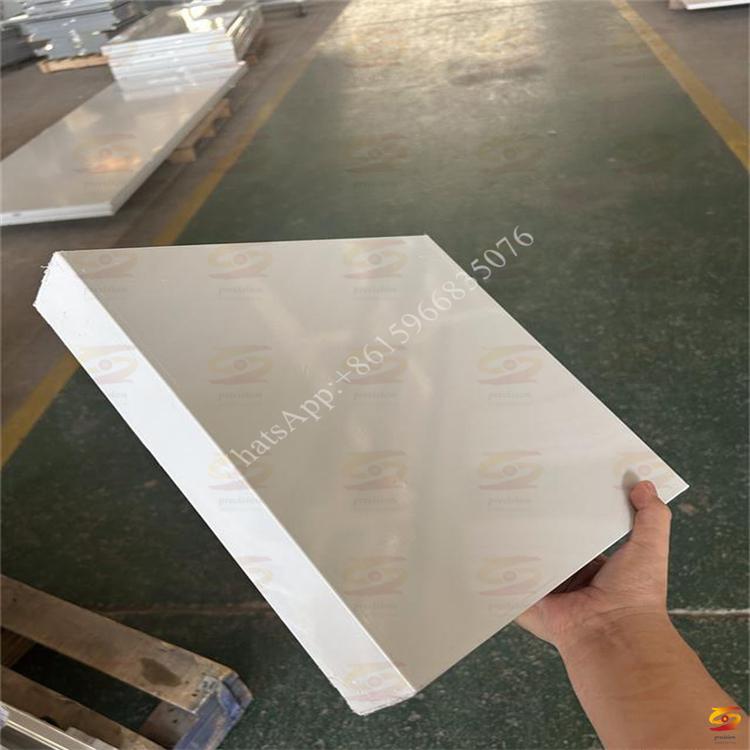

- Precision Cutting: Automated cutting to customer specifications

- Edge Trimming: Four-edge trimming for perfect rectangularity

- Surface Treatment: Optional treatments for specific applications

- Quality Inspection: Comprehensive testing of density, mechanical properties, and dimensions

- Packaging: Moisture-resistant packaging for product protection

5. Process Control and Optimization

Throughout production, sophisticated control systems ensure optimal results:

- Parameter Monitoring: Continuous monitoring of temperature, pressure, speed, and cooling rate

- Automated Adjustments: Real-time process adjustments maintaining quality

- Data Collection: Comprehensive production data recording for analysis

- Efficiency Optimization: Ongoing refinement of process parameters for maximum efficiency

Market Demand and Industry Trends

Global Market Overview

The PET Foam Sheet Machine market is experiencing robust growth driven by increasing demand for sustainable materials:

- Market Size: The global PET foam market is projected to reach $247 million by 2030

- Growth Rate: Compound Annual Growth Rate (CAGR) of approximately 7.50% from 2024-2030

- Regional Distribution: Europe and North America lead in adoption, with Asia-Pacific showing the fastest growth

- Key Players: Equipment manufacturers and PET foam producers forming integrated supply chains

Application Sectors Driving Demand

Wind Energy Sector

The wind energy industry represents the largest application segment for PET foam:

- Market Share: Approximately 30-35% of total PET foam applications

- Application: Core material for wind turbine blades

- Key Requirements: High strength-to-weight ratio, fatigue resistance, and durability

- Growth Drivers: Expanding global wind energy capacity and larger turbine designs

Transportation Industry

The transportation sector increasingly adopts PET foam for lightweight solutions:

- Applications: Automotive components, train interiors, marine structures, aircraft parts

- Benefits: Weight reduction up to 50%, improving fuel efficiency

- Performance Requirements: Lightweight, high-strength, sound insulation, thermal insulation

- Market Trend: Electric vehicle manufacturing driving demand for lightweight materials

Building and Construction

The construction industry utilizes PET foam for its thermal and structural properties:

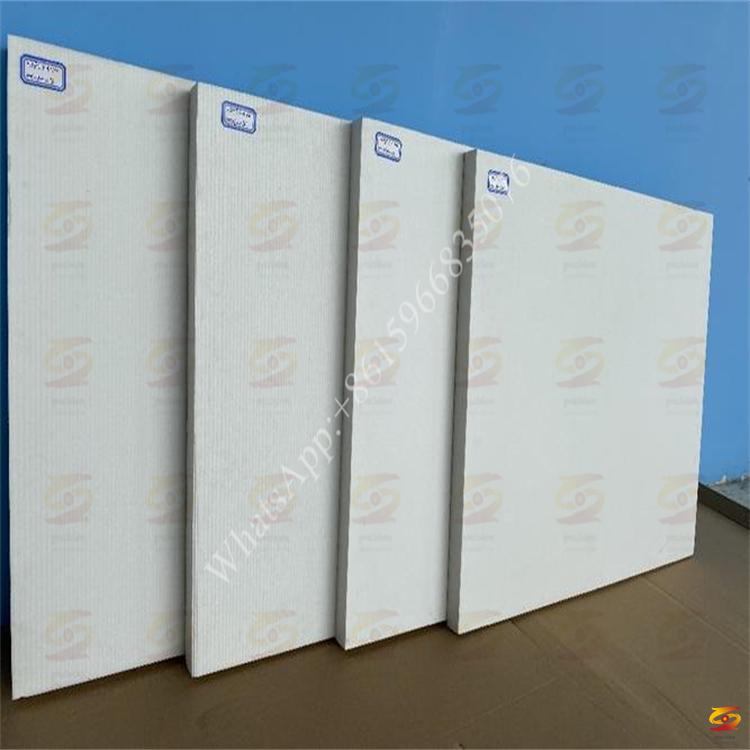

- Applications: Insulation panels, structural elements, decorative boards

- Market Drivers: Increasingly stringent building energy efficiency standards

- Competitive Advantages: Excellent thermal insulation, fire resistance, and mechanical strength

- Growth Potential: Green building market expansion fueling demand

Packaging and Logistics

High-performance packaging applications represent an emerging market:

- Applications: Protective packaging, logistics pallets, shipping containers

- Market Need: Lightweight, high-strength, recyclable packaging materials

- Development Direction: Replacement of traditional EPS and EPE foam packaging

- Growth Factors: E-commerce expansion driving protective packaging demand

Technological Development Trends

The PET Foam Sheet Machine technology continues to evolve:

- Automation Advancement: Fully automated production lines minimizing human intervention

- Smart Manufacturing Integration: IoT and big data technologies for process optimization

- Energy Efficiency Improvements: Energy-saving equipment designs reducing production costs

- Modular Design Approaches: Flexible configurations meeting diverse production requirements

- Multi-functionality: Versatile equipment handling various product specifications

Sustainability and Environmental Trends

Environmental considerations increasingly drive market development:

- Circular Economy Model: Closed-loop recycling systems for PET foam

- Waste PET Utilization: Converting waste PET bottles into high-value foam products

- Life Cycle Assessment: Comprehensive environmental impact evaluation and optimization

- Zero-Waste Production: Minimizing production waste through efficient processes

PVC Foam Replacement

PET foam is increasingly replacing PVC foam due to environmental advantages:

- Environmental Benefits: PET foam is more environmentally friendly than PVC foam, with no harmful substance release

- Market Substitution: Gradual replacement of traditional PVC foam in multiple applications

- Policy Drivers: Environmental regulations promoting PVC alternative materials

- Performance Advantages: Superior performance metrics compared to PVC foam

Market Challenges and Opportunities

The industry faces both challenges and promising opportunities:

Challenges

- Raw Material Price Fluctuations: Unstable PET prices affecting cost control

- Technical Barriers: High requirements for advanced equipment and process technology

- Market Education: New application areas requiring market education and promotion

- Standardization Issues: Incomplete industry standards

- Intensifying Competition: Increasing market participants leading to fiercer competition

Opportunities

- Emerging Market Expansion: Huge potential in Asia-Pacific and Latin American markets

- Technological Innovation Space: Broad space for equipment and process innovation

- Policy Support: Environmental policies and circular economy initiatives

- Cross-Industry Collaboration: Deep cooperation with end-application industries

- Customized Solutions: Specialized equipment and processes for specific applications

Conclusion

The PET Foam Sheet Machine represents a critical technology in the sustainable materials manufacturing landscape. As global demand for environmentally friendly, high-performance materials continues to grow, these advanced production systems offer manufacturers the capability to produce lightweight, strong, and recyclable PET foam products serving diverse industries from wind energy to transportation and construction.

The technology continues to evolve with increasing automation, improved energy efficiency, and enhanced process control. Market growth is driven by stringent environmental regulations, the shift toward circular economy models, and the superior performance characteristics of PET foam compared to traditional materials.

For manufacturers looking to enter or expand in the sustainable materials market, investing in advanced PET Foam Sheet Machine technology offers a strategic opportunity to meet growing market demand while contributing to environmental sustainability goals. As the industry moves toward greater integration of digital technologies and sustainable practices, PET foam production equipment will remain at the forefront of innovation in materials manufacturing.