Characteristics of PVC Yin-Yang corners and comparison with traditional construction

Characteristics of PVC Yin-Yang corners and comparison with traditional construction1. Product characteristics and comparison with traditional construction process

The product is made of high-strength PVC material, which is resistant to corrosion, impact, aging, heat, and has excellent mechanical and mechanical properties. There is no need to use a ruler board during construction, which will change the traditional and cumbersome construction process, so it can also save a lot of wood, at the same time reduce the labor intensity of workers, improve work efficiency by 3-5 times, shorten construction time, and reduce engineering costs. The corners in traditional construction projects are manual construction methods that use cement-covered sand corners, which is time-consuming and consumable. A little carelessness can easily cause vertical misalignment or uneven walls, and the edges made in this way The corner fastness is poor, and it will become a missing corner if it is accidentally collided. It takes time, time and materials to repair and it is not beautiful. Now, we bury high-strength profiles in the corners of the wall, which not only looks beautiful but does not break, but also plays the role of reinforcing ribs to increase the strength on both sides of the corner.

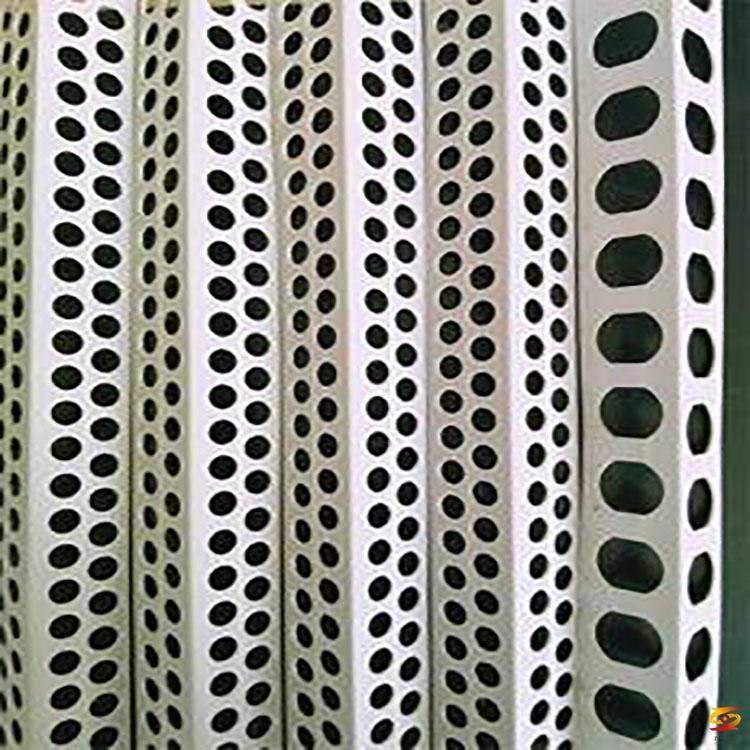

Product features: PVC plastic corner strips are suitable for treatment of plasterboard walls and insulation system wall corners, window corners and other corner treatments. The corner protection strip can be fully combined with joint fillers and thermal insulation mortar to form a strong sun Corner insulation protection system, not rust, alkali resistance, aging resistance, high-strength anti-invasive, effectively guarantee the vertical flatness of the sun corner.

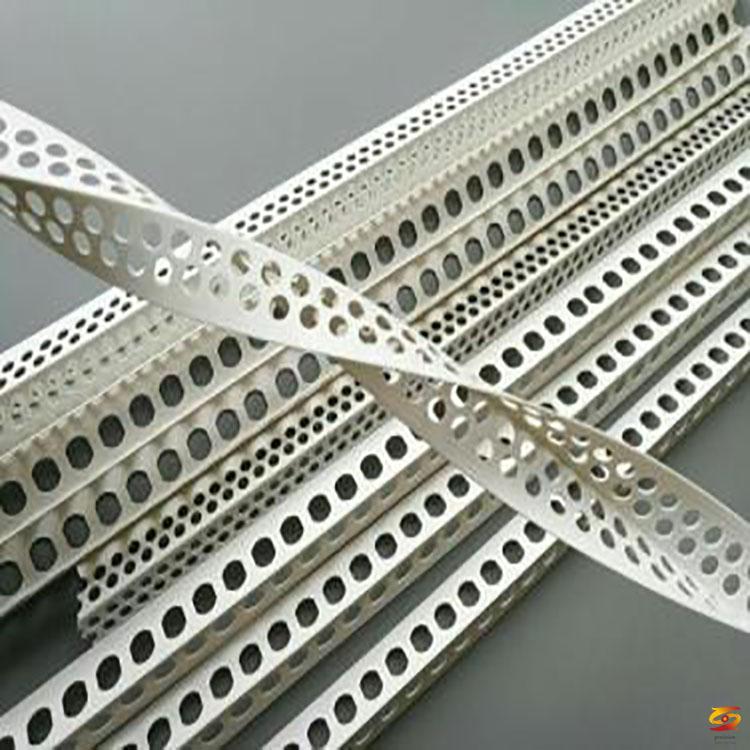

The decoration corner is specially designed for the construction of "yang and Yin corners" in the decoration project, usually with punching, so it is also called "punching strip". This product has been widely used in the construction of indoor and outdoor corners in the international decoration market. With the help of corner construction, it can not only ensure the straight and beautiful lines of the corners, improve the construction speed, but also effectively enhance the firmness of the corners and prevent collisions. Anti-collision function.

"It's better to wipe a surface than to find a line." This is a very vivid expression of the difficulty of construction by the construction workers. The use of decoration angle protection to assist construction completely changes this situation. The construction of corners no longer requires the use of rulers. The traditional and cumbersome construction process becomes very simple and easy to operate. General small workers can master it, and it can also make perfect corner straight lines. ; The use of corner construction can also greatly reduce the labor intensity of workers, shorten the construction time, and reduce the cost of the project; burying high-strength profiles in indoor and outdoor corners can also play the role of reinforcing ribs and improve the collision strength of the corners .

Using corner protector to assist in corner construction, the operation is very simple and can be completed in three steps:

Relying on the previous step, apply the cement paste (white cement: white latex 3: 1, and add appropriate amount of putty powder) to both sides of the corner to be constructed;

The second step, close the corner to the corner of the wall, find out the horizontal or vertical, and then scrape the overflowing cement slurry; The third step, after drying and fixing, rely on the positioning edge on the top of the corner, and then scrape a layer of putty to level it. . Used in indoor and outdoor decoration, in addition to the indoor yin and yang corners that have been commonly used, there are cracks to prevent cracking and repair cracks.

Indoor corner protector

Corner bead is a new type of building material specially designed for difficult construction of wall corners, door corners and window corners. PVC corner bead is famous for its unique weather resistance, corrosion resistance, aging resistance and other characteristics. Its strength and toughness have made people replace steel, wood, aluminum and other traditional building materials with confidence.

The current corner construction process in China follows the traditional construction methods for decades, with low efficiency and cumbersome engineering. Moreover, the corners of the completed buildings are very easy to be damaged during use: on the one hand, it is due to the high contact frequency of the corners, on the other hand, it is due to the insufficient rigidity of the corners. The damaged Yangjiao was not repaired by professional maintenance personnel, which reduced the quality of the project. Especially for the corners of doors and windows, family houses are generally treated with edging, but this method of decoration wastes a lot of wood, wastes a lot of money on decoration, and causes a lot of pollution.

PVC indoor and outdoor yin and yang corner protection strips are made of high-strength polyvinyl chloride raw materials, which are resistant to corrosion, impact, aging, weather, and have excellent mechanical and mechanical properties. Its popularization and use can effectively solve the long-term existence of qualities such as unevenness, unsightlyness, and easy damage of the corners in the construction.

Introduction of PVC plastic Yin Yang angle:

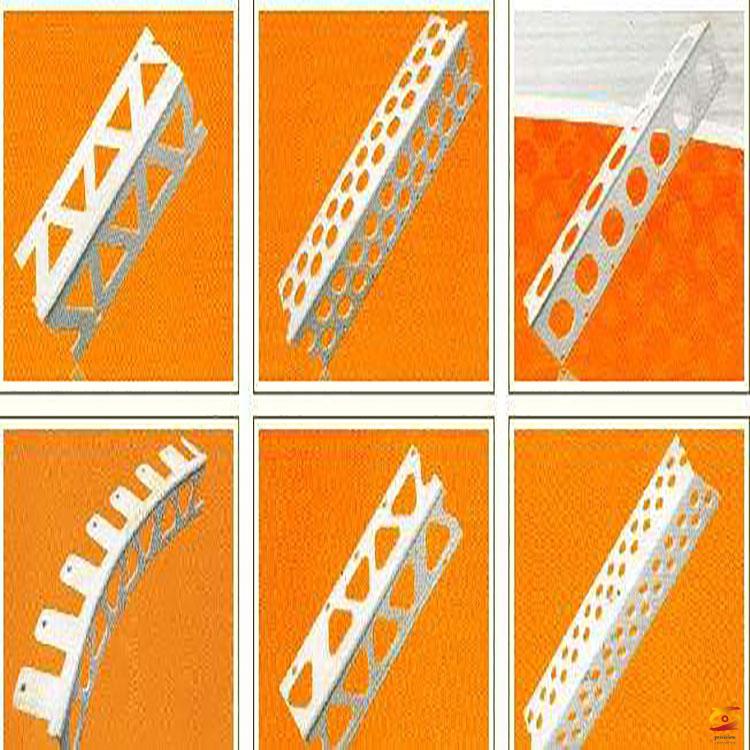

PVC yin-yang corner line is a new construction material applied in the field of building decoration to quickly realize construction. In the 1970s and 1980s, this product appeared in North America earlier, and was later promoted to Europe, South America, West Asia and other places. The purpose of the initial use was to increase the construction speed and achieve straight and beautiful corner lines. Later, people improved its shape Achieved the anti-collision effect, and developed a variety of special modeling wall corner construction products. Such as: male corner, female corner, rounded corners, sharp corners, curved corners, etc. It consists of positioning edges and corner edges. Its characteristics are: the positioning edge and the two corner protection edges form an inverted "Y" shape, the two corner protection edges are perpendicular to each other at 90 °, and the corner protection edges are provided with several fixing holes. The construction method is very simple:

1. Apply mud or putty about 5 cm wide on both sides of the corner;

2. Place the "yin and yang corner" on the corner of the wall, position it horizontally or vertically, and scrape off the slurry overflowing from the cavity;

3. After drying, smear the plaster on the positioning edge as a reference to straighten and straighten.

The appearance of the Yin Yang corner is more due to the increasing labor cost and the continuous improvement of the quality requirements of building decoration. North America, which developed rapidly in the 1970s and 1980s in the last century, encountered the same problem in our country today: labor costs continue to increase, workers It is not easy to find, the construction period is tight, and the acceptance standards are constantly improving. The yin and yang angles came into being in this severe development situation. The application of Yin-Yang angle greatly improves the above problems: ordinary construction not only increases the speed by more than 5 times, but also it is very convenient to operate, and it can be mastered with only simple training. The corner (yin and yang corner) after completion is a step higher than the manual method. With the help of the yin and yang corner shape, the positioning edge construction provided on the styling, the yin and yang corner lines are straight and beautiful, and the smooth line effect is impossible to achieve by manual operation. of!

Features: The batch of scraping stones at the corners of the wall is directly batched into a straight line using this plastic strip, saving time and effort. Don't take it down, owe it directly to the wall. Makes the negative angle and the positive angle 90 degrees more obvious, and the borderline is smoother. Fully protect the yin and yang corners, increase its strength, and avoid the damage of ordinary man-made collisions. It makes the decoration effect quality more fine and the effect is more ideal. It is the best material for the wall decoration. The positive corner of the wall is generally fragile, and it is easy to be injured when moving things. The inner protection is still a bit necessary.

Sun angle construction method:

Step forward: clean up the working surface, remove the protrusions, fill in the depressions;

Step 2: Make paste paddle with putty and mix well;

The third step: wipe the paddle material on both sides of the corner and keep a certain thickness;

The fourth step: close the corner of the sun to the corner of the wall, find out the horizontal and vertical, and scrape the paddle overflowing from the hole;

Step 5: After drying, scrape the putty with the top of the corner as the positioning edge;

Step 6: After drying, sand with sandpaper and complete the construction of latex paint.

Usage: After scraping the putty, cut the product to an appropriate length and press it into the base layer of caulk paste about 5cm (cm) wide just applied on both sides of the yin and yang corners, that is, a layer of 8-10cm (cm) Cover the caulking paste and wait for it to cure, then grant 1-2 layers of Lafarge caulking paste 4-5cm (cm) wider than the bottom layer.

If you want to know more about it please do not hesitate to

contact me. WhatsApp:+86-15966835076.