What Is a Plastic Extrusion Machine?

Understanding Plastic Extrusion Machines: Types, Applications & Future TrendsWhat Is a Plastic Extrusion Machine?

A plastic extrusion machine is a vital piece of industrial equipment used to manufacture continuous plastic products such as pipes, boards, sheets, and profiles. It works by melting plastic raw materials and forcing them through a shaped die to form a specific cross-section.

Plastic extrusion machines are widely used in sectors like construction, agriculture, automotive, packaging, and home improvement.

Main Types of Plastic Extrusion Machines

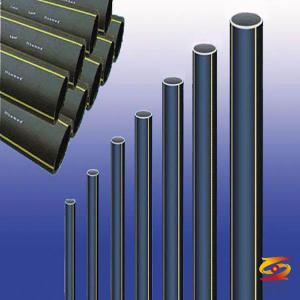

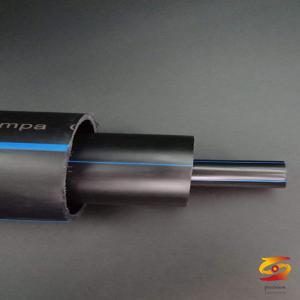

1. Plastic Pipe Extrusion Line

Common Types:

PVC Pipe Extrusion Line

HDPE Pipe Extrusion Line

PP, PPR, and PE-RT Pipe Extruders

Applications:

Water supply & drainage systems

Electrical conduits

Agricultural irrigation

Gas transportation

Hot Keywords:

PVC pipe machine, HDPE pipe extrusion line, PE pipe making machine

2. Plastic Sheet & Board Extrusion Machine

Common Materials:

ABS, PET, PS, PP, PVC

Applications:

Thermoforming packaging

Construction panels

Advertising boards

Refrigerator liners

Hot Keywords:

plastic sheet extrusion line, plastic board extrusion machine, PET sheet extruder

3. Plastic Profile Extrusion Line

Profile Examples:

Window and door frames

Cable trunking

Decorative moldings

Furniture edge bands

Key Materials:

PVC, WPC (wood-plastic composite), ABS

Hot Keywords:

PVC profile extrusion line, WPC profile making machine, plastic molding extrusion machine

Current Market Overview (as of 2025)

Global Demand: Rising due to infrastructure growth, green building trends, and the shift from metal to plastic in many applications.

Energy-Efficiency: Modern machines use twin-screw extruders, infrared heating, and closed-loop control systems to reduce energy and waste.

Smart Manufacturing: Integration of AI diagnostics, IoT monitoring, and automated recipe controls is gaining traction.

Material Focus: There's growing interest in recyclable plastics, bioplastics, and foam extrusion technologies.

Future Trends in Plastic Extrusion Technology

Sustainability First

Biodegradable and recycled plastic extrusion machines are in high demand.

Circular economy solutions are driving design changes in machinery.

Precision Automation

Digital twin technology and smart extrusion lines are improving efficiency, reducing defects, and cutting downtime.

Compact & Modular Design

New extrusion lines are being designed to save factory space and allow easier upgrades or material changes.

High-Speed, Multi-Layer Extrusion

Especially in pipe and sheet production, multi-layer co-extrusion is becoming standard for strength and performance.

Who Needs Plastic Extrusion Machinery?

If you’re in the business of:

Pipe manufacturing

Plastic packaging

Plastic window and door systems

Automotive plastic parts

Sheet or panel production

Then investing in the right plastic extrusion machinery can optimize your production, reduce costs, and increase product quality.

How to Find the Right Machine?

When searching on Google or YouTube, try using high-intent keywords like:

“plastic pipe extrusion machine for sale”

“PVC sheet extruder supplier”

“WPC profile extrusion line China”

“HDPE pipe production line factory”

“custom plastic extrusion machine manufacturer”

These phrases help you connect with manufacturers offering the exact machine you need, whether it’s in China, India, Germany, or other industrial hubs.

Final Tips Before Buying

Check the output capacity (kg/h)

Ask about die and calibration systems

Verify after-sales service & spare part supply

Review energy consumption and automation level

Visit the factory or request video demonstrations if possible

Conclusion

Plastic extrusion technology continues to reshape the modern manufacturing world. Whether you're producing water pipes, packaging sheets, or architectural profiles, choosing the right plastic extrusion machine is key to growth, efficiency, and sustainability.

Looking to upgrade or start your extrusion business?

Start by comparing high-performance machines tailored to your material and product needs. The right investment today brings sustainable profits tomorrow.please contact: Email: sales@plastmachine.cn