SPC floor from beginning to finished product, the whole process

SPC floor from zero to finished product, detailed processPVC floor composition

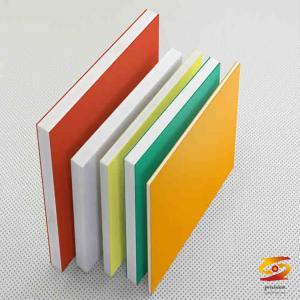

PVC resin powder, stone powder, plasticizer, stabilizer, carbon black, the main components are polyvinyl chloride and stone powder.

The plastic floor is composed of PVC substrate color film decorative paper, wear-resistant layer and UV drench coating in order from bottom to surface.

Stone Plastic Floor SPC

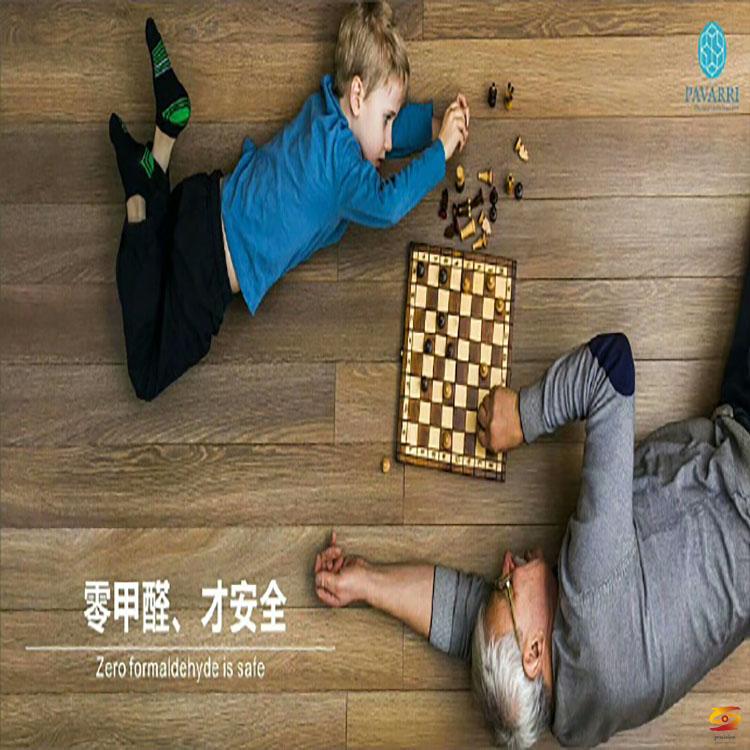

Stone plastic floor SPC is a new type of environmental protection floor developed based on high technology. It has the characteristics of zero formaldehyde, mildew proof, moisture proof, fire proof, insect proof and simple installation.

SPC floor is extruder combined with T-shaped die to extrude PVC substrate, using three-roller or four-roller calender to separately apply PVC wear-resistant layer, PVC color film and PVC substrate, and heat and laminate at one time , The process is simple, the fit is done by heat, and no glue is needed.

SPC floor materials use environmentally friendly formulas and do not contain harmful substances such as heavy metals, phthalates, and methanol, and comply with EN14372, EN649-2011, IEC62321, and GB4085-83 standards. Widely popular in developed countries in Europe and America and the Asia-Pacific market. With its excellent stability and durability, the stone-plastic flooring not only solves the problem of moisture and deformation of the solid wood floor, but also solves the formaldehyde problem of other decoration materials.

There are many patterns to choose from, suitable for indoor decoration, hotels, hospitals, shopping malls and other public places

SPC floor shrinkage: ≤1‰ (after tempering treatment), ≤2.5‰ (before tempering treatment), (shrinkage test standard: 80℃, 6-hour standard);

SPC floor density: 1.9~2 tons/cubic meter;

SPC floor advantages: SPC floor physical indicators are stable and reliable, and chemical indicators comply with international and national standards;

Disadvantages of SPC floor: SPC floor has high density, heavy weight and high transportation cost;

Compared with LVT and WPC floor production, SPC floor production: SPC floor processing and manufacturing process is simple.

Advantages of SPC eco-friendly flooring

SPC floor is a new type of environmentally friendly composite material product, its advantages are as follows:

(1) Waterproof and moisture-proof. It fundamentally solves the problem that wood products are easy to rot and swell and deform after absorbing moisture in wet and watery environments, and can be used in environments where traditional wood products cannot be used;

(2) Insect-proof and termite-proof, effectively prevent insect harassment and extend the service life;

(3) Colorful, with many colors to choose from. Not only has natural wood feeling and wood texture, but also can customize the color according to your own personality;

(4) Strong plasticity, which can realize personalized modeling very simply and fully reflect the personalized style;

(5) High environmental protection, no pollution, no pollution, and can be recycled. The product does not contain benzene and formaldehyde, it is an environmentally friendly product, and it can be recycled to greatly save the wood usage, which is suitable for the national policy of sustainable development and benefits the society

(6) High fire resistance. It can effectively flame retardant, and its fire rating reaches B1 level. It will self-extinguish in the event of fire and will not produce any toxic gas

(7) Good machinability, can be ordered, planed, sawed, drilled, and the surface can be painted;

(8) Simple installation, convenient construction, no complicated construction process, saving installation time and cost;

(9) No cracking, no swelling, no deformation, no need for repair and maintenance, easy to clean, and save later repair and maintenance costs;

(10) The sound absorption effect is good and the energy saving is good, which makes the indoor energy saving up to more than 30%;

(11) Compared with LVTWPC floor, SPC floor has lower investment cost, faster effect, less labor, less labor intensity, and neat environment.

SPC floor production process

Process: 1. Mixing

Automatic metering according to the ratio of raw materials → Hot mixing with high-speed mixer (Hot mixing temperature: 125℃, function

All kinds of materials are mixed evenly, and the moisture in the materials is excluded) → Enter cold mixing (cool the material,

To prevent agglomeration and discoloration, cold mixing temperature: 55℃. )→mix uniform materials by cooling;

Process 2: Extrusion

Join the twin-screw extruder to carry out heating extrusion → enter the sheet die head for extrusion molding, the formed piece

The material passes through a four-roll calender, and the base material is set to a thickness → pasted with color film → pasted with a wear-resistant layer → cooled → cut;

Process 3: UV tempering

Surface UV→tempering (tempering hot water temperature: 80~120℃; cold water temperature: 10℃)

Process 4: slitting and slotting + packaging

Slitting → slotting, trimming, chamfering → inspection → packaging

SPC production process

SPC floor formula (cost about US$300/ton)

PVC 50 KG

Calcium carbonate 150KG

Calcium zinc stabilizer 5KG

Abrasive powder (calcium zinc) 50

Stearic acid 0.8

PE wax 0.6

CPE 3

Impact modifier 2.5

Carbon black 0.5

The above is the basic formula, the formula of each manufacturer is slightly different

Analysis of common problems-poor product molding

1. The product size is unstable, the mold is not full, and the wall thickness is uneven.

Reasons: Unreasonable internal and external lubrication of the formula, unstable quantitative feeding speed, severe wear of the screw barrel, and incorrect fit clearance;

Solution: Improve the ratio of internal and external slip agent, correct feeding failure, replace the barrel and screw, and adjust the gap between barrel and screw.

2. The appearance of the product is uneven, the color deviation is obvious, and irregular fish scales appear on the surface; the product performance is poor; the toughness is poor, the product is brittle and the impact resistance is not qualified;

Reason: The formula structure is unreasonable, the inorganic filling is too high, the plasticization is poor, and the amount of impact material is insufficient;

Solution: Modify the formula structure, appropriately reduce the content of inorganic fillers, correct the plasticization of the material to about 65%, and increase the impact resistance material as appropriate.

3. The output of the finished product is curved, deformed, and partially subsidence;

Cause: The machine head and the shaping die are not on the same plane, the extrusion speed is too fast, the temperature of the cold water is too high, the water pressure is too small, the water flow is insufficient, the water and gas path is not smooth, and the vacuum negative pressure is insufficient;

Solution: Straighten the head die and the shaping die at the same level, reduce the extrusion speed & cooling water temperature, increase the water pressure and flow rate, adjust the vacuum negative pressure to check the water path and air path are unobstructed.

If you want to know more about it please do not hesitate to

contact me. WhatsApp:+86-15966835076.