Analysis of common problems of XPS extruded board

Analysis of common problems of XPS extruded board1. Why does XPS extruded plastic board not absorb water, has low thermal conductivity and good thermal insulation effect?

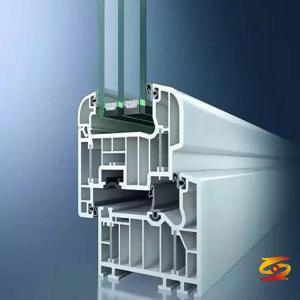

XPS extruded board is made of polystyrene, various additives and foaming agent in the extruder, mixed, melted, pressurized, kneaded and extruded through the die, the pressure is released, the foaming agent is vaporized to form tiny bubbles , Encased in polystyrene film bubble, cooled and shaped to form a honeycomb plate with uniform cross section and closed cell. This structure determines its excellent thermal insulation performance, thermal conductivity is lower than (0.027), because it is a closed-cell structure, the water absorption rate is extremely low.

2. Is the xps extruded board the heavier the weight?

At present, some Chongqing extruded board manufacturers are misleading consumers, saying that the heavier the weight of XPS products, the better. In fact, it is not the first thing to confirm that we need insulation materials, and its purpose is to insulate heat. According to the theory that the heavier the better, the product is not foamed, will we still buy it? The heavier the bulk density, the better the foaming of the product, that is, the poor thermal insulation performance. Is the lighter the better? Nor is it. If the foam is too light, the compressive strength of the product decreases. In order to achieve thermal insulation, XPS extruded board can only play the role of thermal insulation with proper foaming. The uniformity of the cell structure determines the performance of the product.

3. The relationship between bulk density and compressive strength and thermal insulation performance?

The normal requirements of XPS extruded board are: good thermal insulation and high compressive strength. But this is contradictory. High compressive strength, large product capacity, low foaming ratio is required, and thermal insulation performance is reduced; good thermal insulation, high foaming ratio, light product weight, compressive strength is reduced; the appropriate relationship between the two is The key to ensure product performance; to ensure that the product has a high foaming ratio and good compressive strength is the ideal product. That is, the lighter the product's bulk density and the higher the compressive strength, the better the product.

4. The relationship between cell structure and compressive strength and thermal insulation performance?

Cell structure: cell diameter size and cell shape.

Good quality products: the cell structure is the cell size is small and fine, the cell distribution is uniform, the cell shape is round; under the microscope, it is shown as a closed honeycomb structure, the cell is fine and very large, and the cell size is round It has high compressive strength and good thermal insulation performance.

Poor quality products: The structure of the cell is that the cell size is large, the size is uneven, and the size is different. Cells are unevenly distributed, and the cell shape is shown as oblong in the stretching direction or oblong in the thickness direction or oblong in the width direction; under the microscope, the pore size of some open cells is uneven, the cells are thick and foamy The amount of holes is small, the size is oblong, so the compressive strength is poor, and the thermal insulation performance is poor.

5. Is the quality of XPS extruded board made of new materials and recycled materials the same?

The quality of the products produced by new materials and recycled materials is different. The new material polystyrene is polymerized with low-molecular-weight containing double bonds, with a large molecular weight and a long molecular chain. During the molding process, it can ensure that the foaming cell has good film formation, the formed cell is uniform, the cell wall is thin, and the product has high compressive strength. Break down small pieces of product by hand, and can rebound after squeezing hard; the hardness of the new material product is uniform in all directions; the new material product falls gently on the desk surface and emits a soft impact sound; the old material is recycled after many times of high temperature, high pressure and Due to shearing, the molecular chain is cut and shortened, the molecular weight is reduced, the hole breaking rate is increased, the foaming cell film forming property is poor, the cell forming property is poor, the cell wall becomes thicker, the hardness becomes larger, the elasticity is poor, and the product life becomes shorter , Insulation performance becomes poor. Break the small pieces of product by hand, pinch it firmly and don't rebound.

Recycled old products have high skin hardness, soft heart, and the finger does not rebound when pressing the heart;

Recycled old product will make a crisp rigid sound when it is dropped on the desk surface.

6. In order to meet the 65% energy saving requirement, will the replacement of EPS polystyrene board with XPS extruded plastic board cause a significant increase in construction cost?

It will not increase significantly.

Compared with the XPS extruded board and the EPS polystyrene board, the price is higher than the latter, but according to the 65% energy saving standard, the EPS polystyrene board used in the region needs 8-10 cm thick, and the XPS extruded board only needs 5 cm thick. can. Due to different thicknesses and different construction practices, the construction cost of thermal insulation system is almost the same.

XPS extruded board and EPS polystyrene board have different application effects. The thermal resistance coefficient of xps extruded board is basically constant, non-absorbent, high compression and high bearing capacity; the thermal resistance coefficient of eps polystyrene board will gradually increase with time, easy to absorb water, poor compression and bearing capacity, easy aging, and life Do not.

7. What is the flame retardant standard of XPS extruded board?

At present, the new GB8624 "Classification of Combustion Performance of Building Materials (Products)" is under review and will be released soon. The standard adopts the new EU standard. The current national standard GB8624 "Building Materials (Products) Combustion Performance Classification" standard stipulates: B2 level is now the low standard of XPS extruded plastic board (oxygen index ≥26).

If you want to know more about it please do not hesitate to

contact me. WhatsApp:+86-15966835076.