Analysis of PP Hollow Building Formwork Market

Analysis of PP Hollow Building Formwork MarketAnalysis of the current status of the construction template market industry

3.1.1 The building template industry system is gradually formed

As a downstream industry in the construction industry, the construction template industry is obviously affected by the construction industry. my country's construction template industry has undergone a transformation from a single wooden template to product diversification. In the 1970s, my country's architectural form was dominated by brick-concrete structures, and the building template was dominated by wooden forms. In the 1980s, my country's building structure system continued to diversify, and steel-concrete structures became the main form of building structure. Wooden formwork was difficult to adapt to market demand. Practical institutions developed combined steel formwork to partially replace wooden formwork. Since the 1990s, along with the rapid development of my country's economy, the demand for high-rise buildings and large-scale public buildings has been increasing. The original formwork system is difficult to meet the quality, cost, and construction requirements of the project during construction.

Over the years, my country has learned from the successful experience of foreign building templates and developed a variety of new templates on the basis of continuously introducing advanced foreign experience. At present, building templates used in my country's construction market include steel templates, bamboo/wood plywood, aluminum film panels, and plastic templates. With the expansion of the scale of my country's construction template industry, the industry is developing towards formalization, standardization and systematization. The lightweight and environmental protection of template materials has become the development direction.

3.1.2 Demand from the construction industry accelerates the development of formwork industry

The building template is a temporary support structure, and the price of the building template is greatly affected by the newly opened construction area of the real estate. The building template is an important tool for the construction of concrete structures. Experts point out that in cast-in-place concrete structure engineering, formwork engineering generally accounts for 20% to 30% of the cost of concrete structural engineering, accounts for 30% to 40% of the engineering effort, and accounts for about 50% of the construction period. Formwork technology directly affects the quality, cost and benefit of engineering construction. Therefore, the upgrade and development of formwork technology and formwork industry is an important content to promote the progress of my country's construction technology.

With the fiery real estate industry in my country and the launch of various projects, the formwork industry has developed rapidly. From 2012 to 2015, the average annual growth rate of China's construction template industry remained above 10%. By the end of 2016, the output of China's construction template industry reached about 250 million square meters. According to incomplete statistics, the annual use of China's construction template has exceeded 5 100 million square meters.

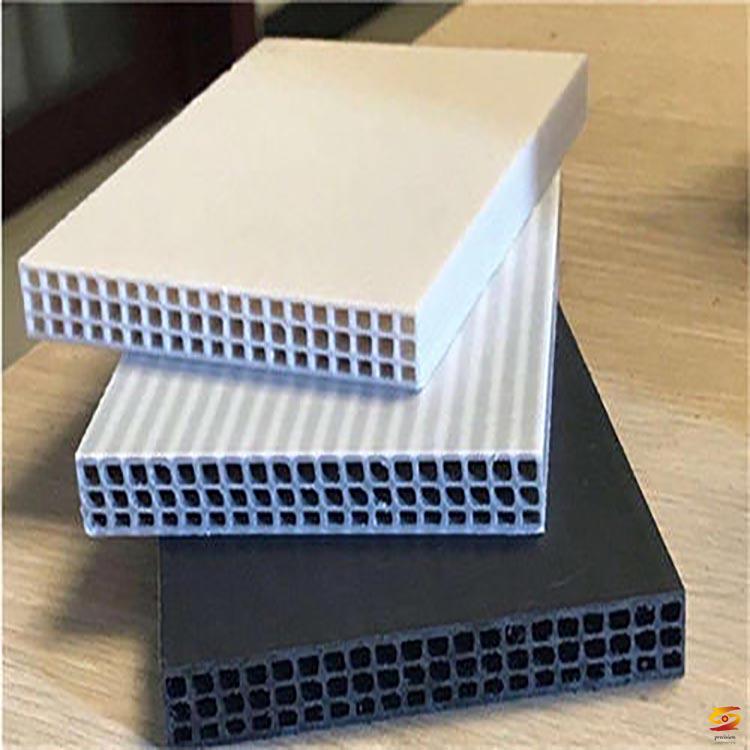

3.1.3 The new PP hollow building template becomes the application direction

In today's society, with the rapid development of the economy and the continuous progress of society, the development and utilization of resources are closely linked with the development of environmental protection, new industrialization, and new urbanization. Therefore, it is urgent to promote the energy-saving and environmental protection applications of building materials in the construction industry. . As an energy-saving and green environmental protection product, plastic building template can completely replace the traditional steel template and wooden template. It is energy-saving and environmentally friendly, and has low amortization cost. It is a new type of replacement product.

PP plastic hollow building template has the characteristics of smooth surface, easy demoulding, light weight, good corrosion resistance, high recovery rate, simple production, etc. It is used as a substitute for wood plywood template in some projects. This project takes advantage of its technology, and uses the use of polymer materials to increase the strength of building templates and improve product performance. The products have outstanding characteristics such as heat and cold resistance, aging resistance, high finish, and strong bearing capacity, which can achieve the replacement of existing building templates.

3.2 Market demand analysis of PP hollow building template project

3.2.1 Rigid demand of PP hollow construction industry accelerates the development of formwork industry

The construction formwork is a temporary support structure. The price of the construction formwork is greatly affected by the newly opened construction area of real estate. The rebound of my country's construction industry accelerates the development of the construction formwork industry. Statistics from the National Bureau of Statistics show that national real estate development investment in 2016 was 102.581 billion yuan, a nominal increase of 6.9% over the previous year. Residential investment was 687.4 billion yuan, an increase of 6.4%. The floor space of houses newly started was 166.928 million square meters, an increase of 8.1%. Among them, the new construction area of residential buildings was 115.91 million square meters, an increase of 8.7%. The floor space of houses completed was 1,06128 million square meters, an increase of 6.1%. The acceleration of the urbanization process and the investment and construction of large-scale public projects will continue to increase the amount of construction projects in my country in a certain period in the future, and the market demand for building formwork is huge.

3.2.2 The energy-saving and environmental protection requirements of PP hollow building templates force the industry to upgrade

In today's rapid economic and social development, the development and utilization of resources are closely linked to the development of environmental protection, new industrialization, new urbanization, etc., so that the vigorous promotion of energy-saving and environmental protection applications of building materials in the construction industry is urgent and can effectively buffer several people. Conflict in the process of economic and social development. It is inevitable to use energy-saving and environmental protection in the mainstream direction of the development of today's construction industry, to achieve the highest efficiency of resource use, and to minimally affect the environment.

The data shows that in 2016, China's total wood consumption was about 60.94 million cubic meters, of which industrial wood consumption was 60.141 million cubic meters, accounting for about 98.69% of the national wood consumption. Plywood production was calculated based on 177.56 million cubic meters. 350 million cubic meters. There are nearly 120 million square meters of bamboo/wood production building templates every year. It is estimated that in order to produce these wooden templates, 17 million large trees with a diameter of 30 cm, or 11,000 hectares of forest area, need to be cut down every year. This 11,000-hectare forest can produce 3 million tons of oxygen per year, 4 million tons of carbon dioxide per year, 1,100 tons of sulfur dioxide per year, and 130,000 tons of dust per year. When energy saving and environmental protection have become the practical requirements of social development, a new type of template product is urgently needed in the building template market to replace the wooden template. The appearance of the polymer building template in this project will make it a reality, and the market development potential is great.

3.2.3 Sharing economy innovation industry development pattern

The global sharing economy is in a period of rapid development. The number of people participating in the sharing economy is increasing, the income of the sharing economy has increased significantly, and the sharing economy has continued to expand. According to the "2016 China Sharing Economy Development Report" recently released by the China E-Commerce Research Center, China's sharing economy market reached 394.5 billion yuan in 2016, with a growth rate of 76.4%. The National Information Center’s Sharing Economy Research Center predicts that in the next few years, China’s sharing economy will maintain an average annual growth rate of about 40%, and the transaction scale will account for more than 10% of GDP by 2020. The sharing economy provides a new way of thinking for the optimal allocation of resources in the economic field, forming the value concept of common use of resources and collaborative consumption.

With the advent of the mobile Internet era, huge marketing dividends, broadened information dissemination and reduced processing costs have greatly released the needs of the general public. This project is based on the actual development of the industry and market demand, and innovative "building template sharing" model Through the rent-and-sale model, the value of resources is shared and the efficiency of resource utilization is improved. At the same time, the model of renting and selling the project will reduce the user's cost of use and is a more economical and efficient operation and service model.

With the development of high-rise buildings, the amount of cast-in-place concrete structures is increasing, which promotes the rapid development of formwork technology. The design and construction technology level of formwork engineering is constantly improved, and the variety and specifications are rapidly increasing. The formwork technology directly affects the quality, cost and benefit of engineering construction, and is an important content to promote the progress of China's construction technology. The implementation of this project will provide the market with new polymer building templates, which have characteristics that are significantly better than existing similar products. Green environmental protection is a high-quality alternative product that adapts to the development of society and industry.

If you want to know more about it please do not hesitate to

contact me. WhatsApp:+86-15966835076.