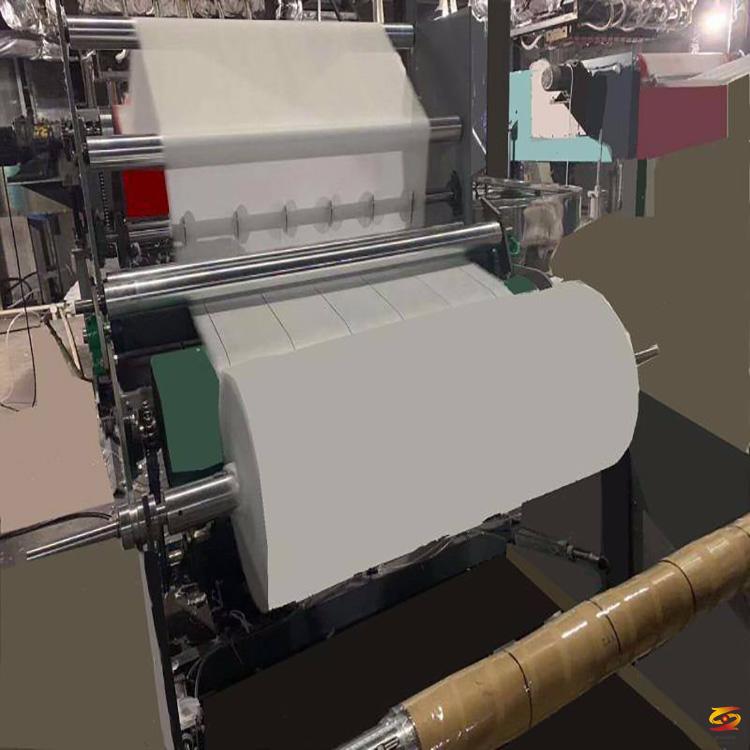

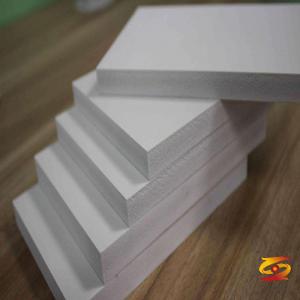

experience share of meltblown cloth making

1, under the condition of high temperature and wind pressure, make the cloth softer.

3. Record the die temperature and screw temperature at this time.

5. The tuyere size is the same as the distance from the spinneret tip to the air knife plane, 1-2mm

6. Adjust the winding speed to achieve the full traction effect.

If you want to know more about it please do not hesitate to

contact me. WhatsApp:+86-15966835076.