a general overview of how to operate a PVC foam board machine

a general overview of how to operate a PVC foam board machine. However, it's important to note that different machines may have slightly different operating processes and methods, so it's always best to consult the manufacturer's instructions for your specific machine.Here is a general operating process and method for a PVC foam board machine:

Preparing the raw materials: The first step is to prepare the raw materials, including PVC powder, foaming agent, stabilizer, and other additives. These materials should be weighed and mixed together in the appropriate proportions.

Feeding the materials into the machine: Once the materials are mixed, they need to be fed into the PVC foam board machine. This is typically done through a feeding system, which can be manual or automated.

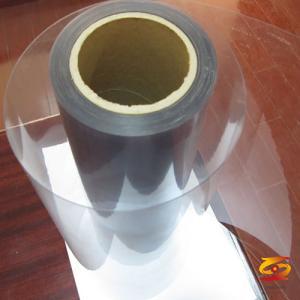

Extruding the foam board: The mixed materials are then extruded through a die, which shapes the foam board into the desired thickness and size. The extrusion process may involve heating the materials to a specific temperature to ensure proper foaming and expansion.

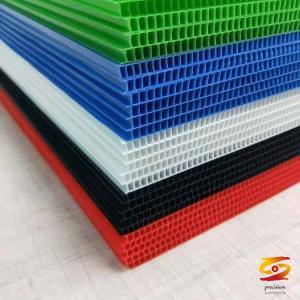

Cooling and cutting the foam board: After extrusion, the foam board is cooled using a cooling system. Once it has cooled, the foam board can be cut to the desired length using a cutting machine or saw.

Finishing and packaging the foam board: Finally, the foam board may undergo additional finishing processes, such as laminating, embossing, or printing. Once finished, the foam board can be packaged and shipped to customers.