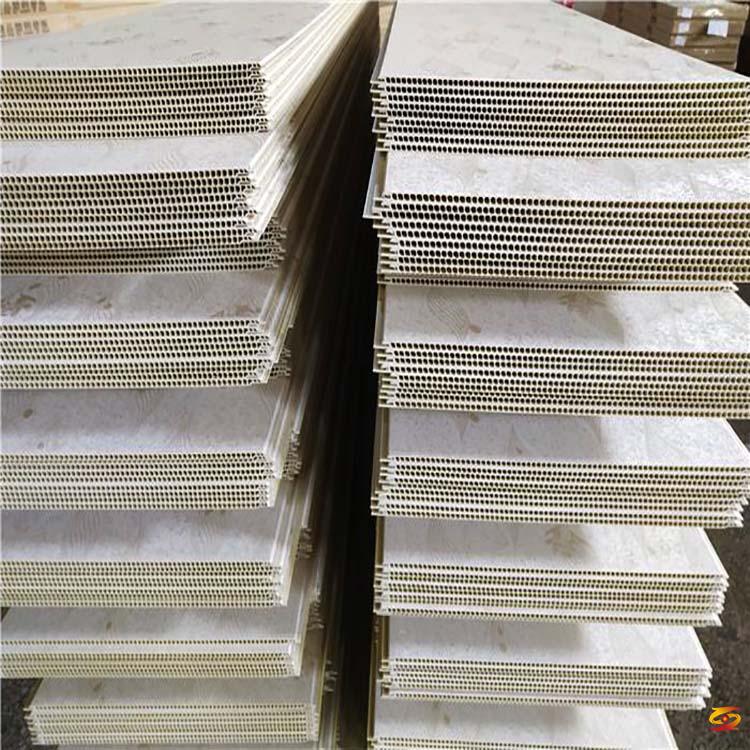

Preparation of integrated board for whole house quick installation

Preparation of integrated board for whole house quick installation:Add a small amount of formaldehyde-free environmentally-friendly adhesive to bamboo fiber, and use the process of drying, pavement into slab, microwave preheating, hot press forming to obtain bamboo fiberboard, its thickness can reach 5mm ~ 18mm, density can It reaches 0.7g/cm<sup>3</sup>~1.1g/cm<sup>3</sup>. Compared with the prior art, this method can not only reduce the production cost and increase the production efficiency, but also improve the quality stability of the fiberboard, and is a fiberboard preparation technology with good application prospects.

1. Manufacturing process of bamboo wood fiberboard integrated wall decoration

1. Additive process: using bamboo fiber and/or wood fiber as raw materials, polyurethane, isocyanate, epoxy resin, and soy gum as adhesives to sizing the raw materials evenly. The quality of the adhesive accounts for 1~ 3.5%;

2. Drying process: dry the raw material after sizing, and control its water content to be 6%-14%;

3. Pavement into slab process: Weigh appropriate amount of raw materials according to the width and thickness of the plate, then pave the raw materials, and then undergo pre-pressing treatment to obtain pre-formed blanks;

4. Microwave preheating process: the preformed slab is fed into a microwave heating device, and the microwave is used to heat the preformed slab temperature to 80 ℃ ~ 180 ℃;

5. Hot press forming process: the preformed slab processed in step 4 is subjected to hot press forming, the hot press temperature is 180°C to 260°C, and the forming pressure is 35kg/cm<sup>2</sup> to 110kg/cm <sup>2</sup>, the pressure holding time is 1min~4.5min.

Whole House Express

The environmental protection integrated wall is a new type of environmental protection and quick decoration material, which is made of the second generation integrated wall, which is made of bamboo wood fiber and waterproof and fireproof crystal powder pressed at high temperature. Since 2010, it began to develop environmentally friendly integrated walls. Through various technical integrations, it officially launched the environmentally friendly integrated wall project to the market in 2011. This product has been passed many inspections and tests by the domestic authoritative department on the quality of building materials and components, acoustic performance, thermal performance, and national fireproof building material quality, all of which comply with national standards.

Second, the advantages of integrated wall

1. Fashionable and elegant: variety, variety of colors, free design according to personal preference, free to match. Western European style, Athens charm, Chinese tradition, Roman style, French style, high-end style and elegant style.

2. Low-carbon environmental protection: all surface treatments are made of environmentally friendly materials, no paint components, no smell in the renovated rooms, no harmful ingredients to the human body, farewell formaldehyde, and truly achieve zero carbon and zero emissions.

3. Insulation: After testing by the national authoritative department, the room temperature difference between the room installed with our products and the ordinary decoration materials is 7 degrees, and 10 degrees compared with the paint. It is the best material for wall decoration in the hot summer in the south and cold winter in the north. This product has unique thermal insulation performance. It can solve the intensity of direct sunlight when applied to the top of balconies, conservatory and villa top floor. If inverter air conditioner is used, it can achieve obvious energy saving effect, and it is a highly recommended environmental protection material by the state.

4. Anti-corrosion and durable: high strength, good toughness, light-weight earthquake resistance, no deformation, not easy to aging, anti-creep, not easy to corrode, long service life, one-time decoration, benefit for life.

5. Moisture-proof and waterproof: good moisture-proof performance, better suitable for wet areas, moisture vapor is difficult to enter, the room is dry and comfortable, no water seepage and no water leakage, let you completely get rid of the trouble caused by wall mildew.

6. Time-saving and labor-saving: the traditional gusset installation method is adopted in the design, which can be directly bent, matched, folded, and the rough wall is directly installed. The installation is not cumbersome in one step. The ordinary woodworker can save you from The decoration period is too long and annoying.

7. Easy to clean: The surface is treated with advanced foreign technology, which is not only stylish and beautiful, but also easier to clean and hygienic. It can be directly scrubbed with water without foaming and deformation, making your life easier.

8. Super sound insulation: the sound insulation effect can be up to 29 decibels after testing by the national authority, which is equivalent to the sound insulation effect of solid walls. The whistle sound, machine noise and car roar no longer bother your life, the room is quiet and comfortable, and you A quiet sky.

9. Super-hardness: Take the original bamboo and wood fiber as the base material, composite environmental protection materials, enhance the hardness strength, impact resistance, friction resistance, not afraid of scratches, make your life better.

If you want to know more about it please do not hesitate to

contact me. WhatsApp:+86-15966835076.