Do you really know what is "extrusion"?

Extrusion

Refers to the role of materials through the barrel and screw of the extruder. In the processing of non-rubber extruders, the pressure of the extruder is used to press the extrusion of the die itself. It is a kind of processing method to make various cross-section products or semi-products by continuously passing through the head while being plasticized by heat while being pushed forward by the screw.

table of Contents

1 Brief description

2 equipment

3 related parameters

4 features

5 Development Trend

Brief description

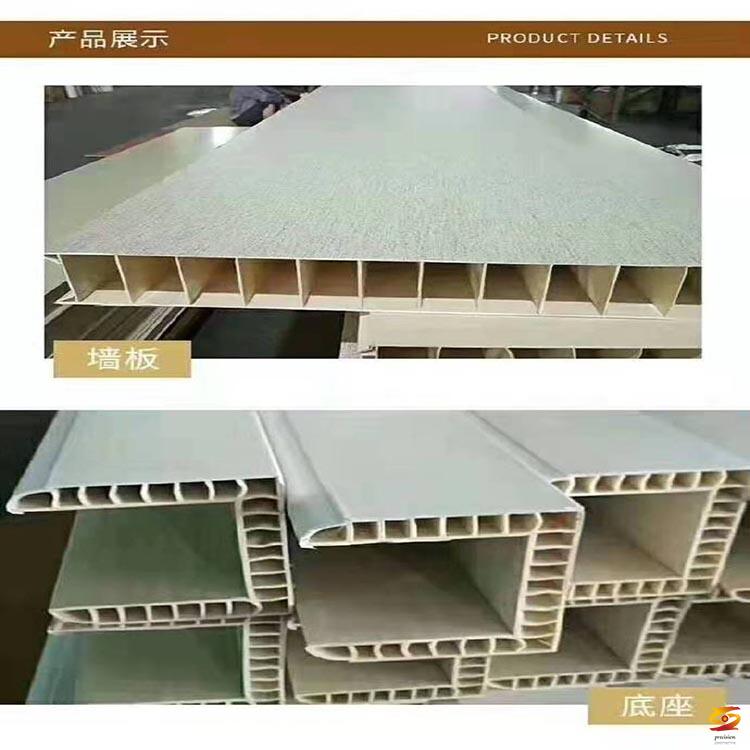

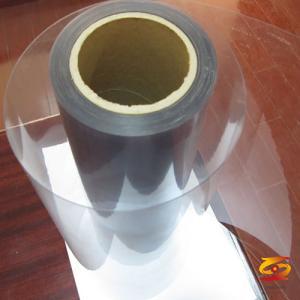

Extrusion molding is a high-efficiency, continuous, size, and wide-surface molding processing method. It is an early technology in the processing of polymer materials. After more than 100 years of development, extrusion molding is produced in the field of polymer processing. The molding method with the most varieties, the biggest changes, high prediction, strong adaptability, wide application, and the largest proportion of output. Extrusion molding is one of the most important forms of plastic material processing. It is suitable for most plastic materials except some thermosetting plastics. About 50% of thermoplastic products are completed by extrusion molding. Molding of fibers, thermoplastic elastomers and rubber products; extrusion molding method can produce continuous products of various forms such as pipes, rods, sheets, profiles, wire and cable sheaths, monofilaments, etc. , Plasticization, granulation, coloring and blending modification of polymer materials, etc. Moreover, based on extrusion molding, extrusion-blow molding technology and extrusion-tentering technology combined with inflation, stretching and other methods are important methods for manufacturing films and hollow products.

Extrusion molding (Extrusion Molding), also known as extrusion molding or extrusion molding, mainly refers to the squeezing action of the transfer screw or screw, so that the heated molten polymer material is forced to pass through the die of the machine head under the pressure of the pressure [1 ] The extrusion molding process mainly includes feeding, melt plasticizing, extrusion molding, shaping and cooling.

device

1, the host

Extrusion system: composed of screw and barrel, it is the key part of extruder. Its role is to plasticize the material, quantitative, constant pressure, constant temperature extrusion melt

Transmission system: drives the screw to provide the required carbide and torque

Heating and cooling system: to ensure that the temperature of the plastic and extrusion system during the molding process meets the process requirements

2. Auxiliary machine

Composed of machine head, shaping device, cooling device, traction device, winding device, cutting

3. Control system

Consists of electrical appliances, meters and actuators

Function: control the main and auxiliary motors, add the required power and power; control the temperature, pressure and flow of the main and auxiliary machines to ensure the quality of the products; realize the automatic control of the extended unit to ensure the coordinated operation of the main and auxiliary machines.

Related parameters

1. Temperature

The temperature is controlled by the heating and cooling system. Due to the structure of the screw, the screw of the heating and cooling system, and the change of the screw, the temperature of the extruded material fluctuates both radially and initially, which affects the quality of the product. Stress, dull and dull surface. To ensure product quality, the temperature should be stable.

2. Pressure

Due to the resistance of the screw and barrel structure, the machine head, the filter screen, and the filter plate, there is pressure inside the plastic. The pressure changes regularly, and the pressure also changes.

3. Extrusion speed

However, when the product has been determined, when the unit has been extruder die quality or length of plastic extruded. Factors affecting the extrusion rate: head inverter, screw and barrel structure, screw conversion, heating, cooling system, plastic properties. The expansion rate is also related to the screw rotor. There are also variables in the expansion rate that affect the geometry and size of the product.

Features

Compared with other polymer molding methods, extrusion molding has many outstanding advantages.

(1) Continuous production can produce pipes, plates, rods, profiles, films, cables and monofilaments of any length as required.

(2) High production efficiency The single machine output of the extruder is greater. For example, an extruder with a diameter of 65mm can produce polyvinyl chloride film with an annual output of more than 450t.

(3) This processing method with a wide range of applications is widely used in the processing of rubber, plastics, and fibers, especially plastic products. Almost thermoplastics and some thermosetting plastics can be processed by this method. In addition to directly shaped products. It can also be mixed, plasticized, granulated, colored, billet shaped, etc. by extrusion method, such as extruder and calender to produce rolled film; with extruder to produce various compression molded parts; and blow molding The machine can cooperate to produce hollow products. In the production process of rubber products, the extrusion method is used to manufacture treads, inner tubes, hoses and various products with complex cross-sectional shapes, as well as semi-finished products such as hollow, solid, rubberized, etc., even in petrochemical plants, during the production of resins. The extruder squeezes to remove water from the resin, and the extruder is used to complete the mixing of additives and modifiers in various brands of resin to complete the resin granulation process.

(4) One machine and one extruder can process a variety of materials and products. As long as the different screws and heads are replaced according to the material performance characteristics and product shape and size, different products can be produced.

(5) Simple equipment, less investment and injection molding, rolling ratio, simpler extrusion equipment, easier manufacturing, equipment cost expenditure, and more convenient installation and debugging. The volume of equipment is relatively simple for the plant and supporting facilities.

development trend